1. Introduction

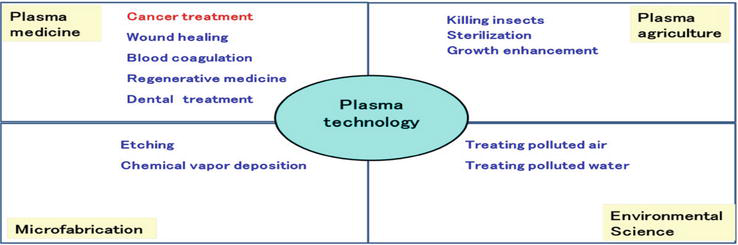

“Plasma is a quasineutral gas of charged and neutral particles which shows collective behavior.” The neutral gas ionization contains equal numbers of positive and negative charge carriers (ni ≈ ne ≈ n). Where ni is ion density, ne is electron density, and n is number density. Such plasma is called “quasineutral.” Irving Langmuir in 1926, first used the term plasma to explain an inner region of electrical discharge. Plasma has different types depending on many factors such as pressure, temperature, and charges particle density. Commonly used types are nonthermal atmospheric pressure plasma (cold plasma) where Te > Ti > Tg, and hot plasma where Te ≈ Ti. The temperatures of electrons, ions, and gas molecules are shown here as Te, Ti, and Tg, respectively [1]. Cold atmospheric plasma (CAP) is produced by subjecting gases such as helium, argon, nitrogen, oxygen, or air to a high-voltage, high-frequency electrical discharge. In large number of applications, nonthermal plasma is commonly used as they produce a variety of reactive species, such as reactive nitrogen species (RNS), reactive oxygen species (ROS), or both reactive oxygen and nitrogen species (RONS) [2]. Plasma physics is now emerging at a fast pace. Some of its applications are plasma medicine, plasma agriculture, microfabrication, and environmental science which are described below (Figure 1).

Figure 1.

Wide applications of plasma technology in daily life. There are many applications of plasma such as plasma medicine, plasma agriculture, microfabrication, and environment science [

1.1 Plasma medicine

Plasma medical science is a unique interdisciplinary field that includes studies on plasma science and medical science. Cancer, wound healing, blood coagulation, regenerative medicine, and dental treatment have all benefited from the use of nonthermal atmospheric pressure plasma (NTP) in medicine. It has been extensively studied how plasma interacts with cells and tissues. NTP can be used in two different ways in plasma medicine. The first is direct treatment, which involves bringing plasma into direct contact with the biological material to be treated. In this treatment, all plasma-generated species, both short lived and long lived species come into close contact with the sample and work synergistically. The second method is known as indirect treatment. In this procedure, plasma is used to activate a liquid medium, which is then used for treatment. Only long-lived chemical species are involved in this case [4]. Plasma-assisted immune therapy and plasma-activated medium are two examples of indirect treatments. In plasma cancer treatment, managing intracellular redox equilibrium may be crucial. Animal studies are necessary to evaluate the efficacy and safety of these medicines for potential therapeutic use. The use of plasma diagnostics, such as vacuum ultraviolet absorption spectroscopy (VUVAS), optical emission spectroscopy (OES), two-photon absorption laser-induced fluorescence (TALIF), and laser-induced fluorescence techniques, is crucial for understanding the features of plasma. Electron spin resonance (ESR) and colorimetric assays are two techniques for examining liquids exposed to plasma. Techniques include cell viability assays, immunostaining, live imaging, apoptosis assays, reactive oxygen species (ROS) assays, western blotting, flow cytometry, and real-time polymerase chain reaction (PCR), which can be used to examine cells exposed to plasma. Pen-type plasma sources are important for practical use in medicine. Sakakita and Ikehara have developed a mild-type plasma generator for blood coagulation [3]. Platelet-rich plasma (PRP) is a regenerative medicine. PRP is frequently employed as fillers or in operations for skin rejuvenation in the fields of cosmetic medicine and cosmetology. It is injected at the musculoskeletal and tendon injury site, and early results indicate promising structural and functional benefits. A recognized and accepted practice in dental treatment regimens is PRP therapy. PRP injections into nonhealing or chronic wound sites or their use as a dressing have demonstrated promising therapeutic results in wound healing trials. The capacity of PRP to produce various growth factors, cytokines, and interferons is thought to be the cause of its therapeutic effects. When used in addition to traditional wound care procedures, they encourage fibroblast proliferation, angiogenesis, epithelial cell proliferation, and wound healing [5, 6]. In addition, carbon monoxide (CO) also shows a synergistic effect with plasma. It plays a key role in the suppression of organ graft rejection, cardiopulmonary bypass surgery, and pancreatic cancer [7].

1.2 Plasma agriculture

The research on NTPs used to treat seeds and plants that were done with knowledge gained in plasma medicine served as the starting point and the basis for the new field known as “Plasma Agriculture.” Such interdisciplinary study is required due to the population growth-related constant rise in food demand. One such strategy is using NTPs in agriculture, which allows for a significant output improvement without additional water or chemical fertilizer. NTPs are extremely effective and valuable, and they have already demonstrated this in several applications in the food sector, completing the entire food cycle. For a very long time, plasmas in the food processing industry were restricted to cleaning packaging materials or their treatment to increase their wettability, sealability, printability, and barrier qualities [8]. Typically, seed treatment protects it against pathogens that could harm the seed during the early stages of seedling development. The agriculture industry’s top concern is the presence of microorganisms (bacteria and fungi) that will impact crops. By employing plasma processing techniques, bacteria can be inactivated while seed germination and crop growth are accelerated. Some plasma processing techniques provide a variety of benefits, including quick processing times and low treatment temperatures. To guarantee speedy and uniform germination, more effective seed treatment solutions should not contain hazardous residues, require minimal energy, have a modest penetration depth to avoid harming cells, and favor lengthy storage period while supporting good seed growth. NTP therapies may be able to meet these criteria. By etching, adding functional groups, and covering with unusual materials, plasma can interact with seeds and change their surface features. Plasma treatment of seeds can improve crop germination and seedling growth by removing microbial layers and changing water intake and other factors [9].

Pesticides are sprayed on crops in agricultural fields and plant protection facilities to shield them against a variety of insects and viruses. Foods including cereals, fruits, vegetables, and meats can become contaminated by fungi like Aspergillus or Penicillium. The environment and the human body are both harmed by leftover agricultural chemicals, such as thiabendazole, imazalil, and ortho-phenylphenol. Additionally, methyl bromide is a powerful and frequently employed pesticide. When used for inactivation, NTP and low-pressure plasmas showed promise as a very effective technique that produces the least amount of harm to crops, foods, seeds, people, and the environment [10, 11]. Further, salt-induced suppression of rice seed germination can be alleviated by using an exogenous CO aqueous solution. CO can enhance seed germination. CO has also been shown to stimulate lateral root development in various seeds [7].

1.3 Microfabrication

The development of plasma science and technology has significantly emphasized plasma-assisted microfabrication, particularly since the 1970s. This growing tendency can be largely attributed to “Moore’s Law,” which states that the number of transistors in a compact integrated circuit doubles approximately every two years [12]. Low pressure, NTPs have several significant uses in the processing of semiconductors for producing microelectronic devices and integrated circuits. Sputtering, plasma-enhanced chemical vapor deposition (PECVD), plasma oxidation (anodization), and planarization are a few examples of film deposition processes. Film removal procedures include etching, stripping, cleaning, and plasma resist development. Currently, polycrystalline silicon (“poly”), silicon dioxide (“oxide”), and metals (often interconnect materials like aluminum-copper alloys and, increasingly, tungsten) are etched using plasma at essential steps. Amorphous silicon, silicon dioxide, and silicon nitride thin films are frequently deposited using (PECVD) techniques. Related technologies for producing large-area thin film transistors for flat panel displays are of great interest [13].

1.4 Environmental science

Volatile organic compounds (VOCs) are contaminants present in various industrial settings, including paint, coatings, and chemical manufacturing facilities as well as semiconductor manufacturing facilities. Utilizing NTP produced at atmospheric pressure or above is one of these traditional VOC abatement techniques. High energy electrons and low gas temperatures are characteristics of atmospheric pressure nonthermal discharges such as DC or AC corona discharges, microwave plasma, and dielectric barrier discharges (DBDs). After years of research, plasmas are showing promise as a VOC remediation technique. Carbon dioxide and water are the major byproducts of the VOC breakdown if enough oxygen is available. Since almost 150 years ago, ozone has been produced industrially using the DBD technique, which is frequently utilized for NTP production at atmospheric pressure. The actual gas temperature is close to ambient temperature, which is cool enough to provide a noncorrosive processing environment while still supporting a variety of chemical reactions that destroy the pollutant. In contrast to the energetic electrons, whose temperatures range from 10,000 to 100,000 K, active radicals, ionic, and excited and dissociated atomic and molecular species, can start plasma chemical processes. DBDs have a significant advantage over other discharges in that the reaction conditions of plasma processing can be adjusted to maximize the average energy of the electrons by varying the gas pressure (or gas density) or discharge gap width. Plasma technology for air pollution control currently has a low energy efficiency and produces harmful byproducts such as CO, NOx, and nitric acid when processing in air streams, despite its demonstrated ability to destroy waste gas streams [14, 15].

2. Green technology

One of the industrial sectors that contributed significantly to the advancement of human civilization throughout history is the textile industry, the second-largest industry in the world. But textiles and its end products consume a lot of water, complex chemicals, and energy, making it one of the top 10 most polluting world’s industries. Application of new and innovative technologies is necessary to address the primary demands of environmental protection from pollution. The large area of plasma science has one such technology. Plasma technology has been used in several applications and is now recognized as a flexible tool for improving industrial processes. NTPs are excellent for modifying the surfaces of heat-sensitive textile polymers. The pretreatment and finishing of textiles are done using plasma because it improves the surface properties of polymers without changing their bulk qualities. In order to decrease energy use and pollutant production, NTP integration into traditional energy-intensive wet-chemical textile manufacturing is becoming increasingly popular [16].

Abbreviations

Cold Atmospheric Plasma | |

Reactive Nitrogen Species | |

Reactive Oxygen Species | |

Reactive Oxygen and Nitrogen Species | |

Nonthermal atmospheric pressure plasma | |

Vacuum ultraviolet absorption spectroscopy | |

Optical emission spectroscopy | |

Two-photon absorption laser-induced fluorescence | |

Electron spin resonance | |

Polymerase chain reaction | |

Platelet-rich Plasma | |

Carbon monoxide | |

Plasma-Enhanced Chemical Vapor Deposition | |

Volatile organic compound | |

Dielectric barrier discharge |

References

- 1.

Shahzad A, Ahmed Z, Kashif M, Sohail A, Manzoor A, Hanif F, et al. Large Scale Simulations for Dust Acoustic Waves in Weakly Coupled Dusty Plasmas. Croatia/London, UK: INTECH Publisher; 2022 - 2.

Abduvokhidov D, Yusupov M, Shahzad A, Attri P, Shiratani M, Oliveira MC, et al. Unraveling the transport properties of RONS across nitro-oxidized membranes. Biomolecules. 2023; 13 (7):1043 - 3.

Tanaka H, Ishikawa K, Mizuno M, Toyokuni S, Kajiyama H, Kikkawa F, et al. State of the art in medical applications using non-thermal atmospheric pressure plasma. Reviews of Modern Plasma Physics. 2017; 1 :1-89 - 4.

Shahzad A, editor. Plasma Science and Technology. London, UK: IntechOpen; 2022. DOI: 10.5772/intechopen.95256 - 5.

Popescu MN, Iliescu MG, Beiu C, et al. Autologous platelet-rich plasma efficacy in the field of regenerative medicine: Product and quality control. Hindawi BioMed Research International. 2021; 2021 :4672959, 6 pages - 6.

Cognasse F, Hamzeh-Cognasse H, Mismetti P, Thomas T, Eglin D, Marotte H. The nonhaemostatic response of platelets to stress: An actor of the inflammatory environment on regenerative medicine? Frontiers in Immunology. 2021; 12 :741988 - 7.

Carbone E, Douat C. Carbon monoxide in plasma medicine and agriculture: Just a foe or a potential friend? Plasma Medicine. 2018; 8 (1):93-120 - 8.

Pankaj SK, Bueno-Ferrer C, Misra NN, Milosavljević V, O’donnell C, et al. Applications of cold plasma technology in food packaging. Trends in Food Science & Technology. 2014; 35 (1):5-17 - 9.

Shahzad A, He M, editors. Emerging Developments and Applications of Low Temperature Plasma. Hershey, PA, US: IGI Global; 2021 - 10.

Randeniya LK, de Groot GJ. Non-thermal plasma treatment of agricultural seeds for stimulation of germination, removal of surface contamination and other benefits: A review. Plasma Processes and Polymers. 2015; 12 (7):608-623 - 11.

Kinay P, Mansour MF, Gabler FM, Margosan DA, Smilanick JL. Characterization of fungicide-resistant isolates of Penicillium digitatum collected in California. Crop Protection. 2007; 26 :647 - 12.

Hamaguchi S, Agarwal S, Zajickova L, Wertheimer MR. Plasmas for microfabrication. Plasma Processes and Polymers. 2019; 16 (9):1990001 - 13.

Graves DB. Plasma processing. IEEE Transactions on Plasma Science. 1994; 22 (1):31-42 - 14.

Hackam R, Akiyama H. Air pollution control by electrical discharges. IEEE Transactions on Dielectrics and Electrical Insulation. 2000; 7 :654 - 15.

Kim H-H. Nonthermal plasma processing for air-pollution control: A historical review, current issues, and future prospects. Plasma Processes and Polymers. 2004; 1 :91 - 16.

Dave H, Ledwani L, Nema SK. Nonthermal plasma: A promising green technology to improve environmental performance of textile industries. In: The Impact and Prospects of Green Chemistry for Textile Technology. Cambridge, UK: Woodhead Publishing; 2019. pp. 199-249