The Saaty rating scale for deciding relative importance of factor i compared to factor j [17].

Abstract

The increasing use of energy storage in batteries has been contributing to the electric sector technological advancement, specially to guarantee of continuous supply in periods of intermittence or low production. In this work the problem of selecting batteries for application in the quality of energy supply is addressed. A methodology to size and classify the best battery technology based on the multicriteria decision-making method AHP (Analytic Hierarchy Process) was developed. The opinions of specialists in the area were considered for the avaliation to four types of criteria: environmental, technological, regulatory and financial. Finally, to evaluate the developed approach a problem of classifying four different battery alternatives (Ventilated Stationary Tubular Lead Acid, Lead-Carbon Acid, Ventilated Stationary Lead Acid, and Lithium Ion LFP) was tested and the result pointed to the Ventilated Stationary Lead Acid technology as the best alternative. In addition, analyses using theoretical scenarios with preferences in certain criteria were performed. The methodology proved applicable, considering that with the input data provided by the decision maker, it is possible suggest the best technological alternative for a given purpose. The simulations carried out suggest that the methodology has potential to evolve and act in a real situation.

Keywords

- energy storage system

- battery

- multicriteria decision-making algorithm

- analytic hierarchy process

- Brazilian electrical system

1. Introduction

The supply of energy, in times of intermittency or low production, can be assured through energy storage systems (ESS). Efficient management of energy storage is crucial in the process of achieving a balance between power quality, efficiency, costs, and environmental constraints [1]. In Brazil, for example, it is estimated that by 2023 its market will use around 95 GWh in energy storage systems, and this number corresponds to 50% of all installed capacity in the world at the end of 2015 [2].

ESS, in particular battery energy storage systems, are the most frequently installed options to facilitate the use of renewable energy [3], and batteries have been maturing for several decades and increasing their reliability and durability. In Germany, the market for stationary battery storage systems is growing rapidly compared to pumped storage systems [4]. Taking into account the expected increase in consumption of this technology for the coming years, it is expected, as a reflection of its large-scale use, a gradual reduction in its acquisition and implementation costs.

The choice of batteries for energy storage is a complex decision, as it needs to take into account several technical, economic, regulatory, and environmental criteria. In this sense, the multicriteria decision-making (MCDM) methods can serve as a decision support tool.

Conventional MCDM methods are frequently used in the energy field [5] in a wide range of problems [6, 7, 8, 9, 10, 11, 12]. In [11], the combination of analytic hierarchy process (AHP) and Vise Kriterijumska Optimizacija I Kompromisno Resenje (VIKOR) methods are used to select the best solution for electrical power supply in remote rural locations. The evaluation and classification of renewable energy sources are addressed as an MCDM problem in [10], based on the theory of gray systems. The problem of selecting investment projects for solar thermal power plants addressed in [12] uses the AHP and Analytic Network Process (ANP) methods.

More specifically in the energy storage problem, we also have the applicability of MCDM methods [1, 13, 14, 15, 16]. In [16], an attempt is made to determine the most appropriate among six energy storage alternatives, considering four main criteria and 16 subcriteria. For this, a hybrid methodology is used that combines AHP and Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) based on type 2 fuzzy sets. In [15], a decision support tool is proposed for the selection of energy storage alternatives. Considering a multi-objective optimization approach based on the augmented

A literature review of the main MCDM approaches in evaluating ESS is provided in [3]. As seen earlier, among the multicriteria decision-making methods, we have the AHP method created by the mathematician Thomas L. Saaty [17, 18]. This approach consists of evaluating criteria through a measurement scale, organizing them in a hierarchical structure [18]. Since this is a flexible decision support method, which can take into account objective and subjective criteria by comparing pairs of criteria [19], in the subjective criteria we can consider the opinion of specialists in an area of knowledge. Its use in its original form or in hybrid approaches has applications in several problems in the energy sector [8, 20, 21, 22, 23, 24, 25, 26].

Given the growing demand for ESS technologies, especially batteries, here we develop a multicriteria analysis methodology based on the AHP method, which is one of the most traditional MCDM methods used in a wide range of energy field problems. The main objective of this approach through AHP is to help choose the best battery technology for energy storage, considering for this, technical, regulatory, environmental, and economic criteria and subcriteria through the opinions of specialists in the area.

This chapter is organized as follows. In Section 2, we make a brief summary of the AHP method. In Section 3, we present the methodology developed to choose the best battery technology for energy storage using the AHP method. To validate the developed methodology, we performed numerical experiments in Section 4, considering an analysis of a scenario based on expert opinion and another analysis based on theoretical scenarios. Finally, in Section 5, we present our conclusions.

2. Brief review of the AHP method

Decision theory is the set of techniques that help decision-makers to recognize the particularities of a problem and structure it. In this context, MCDM refers to determining the best option in relation to multiple and often conflicting criteria [27].

Among the traditional methods of MCDM, we have the AHP method which has already been applied in various problems in the energy field, such as renewable energy [26, 28, 29, 30], energy storage [3, 13, 21, 31, 32, 33], site selection for wind farms [22, 34, 35, 36], among others [37, 38, 39, 40].

This method was created by the mathematician Thomas L. Saaty in the 70s [17, 18], being a method used to solve problems with multiple criteria and which emphasizes modeling according to the knowledge of specialists in the area. This method considers quantitative and qualitative aspects and can be used both to identify the best possible alternative and also to list the alternatives according to a ranking of priorities.

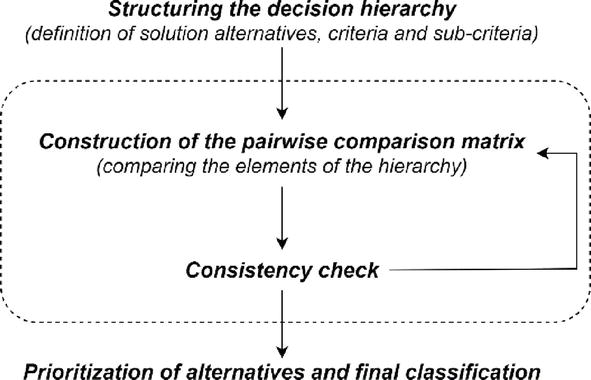

One of the advantages of using the method is the consideration of the experience of the decision-maker who can intuitively assign weights to the relevant criteria by comparing them pair by pair. Figure 1 describes the steps of this method.

Figure 1.

Steps of the method AHP.

First, the alternative solutions to the problem are listed, and the criteria and subcriteria for choosing the alternatives are listed. Then, based on the judgment of the decision-makers, scores are assigned to each criterion following the Saaty scale [17, 18], as described in Table 1.

| Intensity of importance | Description |

|---|---|

| 1 | Equal importance |

| 3 | Moderate importance of one over another |

| 5 | Essential or strong importance |

| 7 | Very strong importance |

| 9 | Extreme importance |

| 2, 4, 6, 8 | Intermediate values between the two adjacent judgments |

| Reciprocals | If judgment of factor i compared with factor |

Table 1.

Each criterion/subcriteria are judged pair by pair, and this judgment is represented through a square decision matrix

must satisfy the equation Eq. (2):

where

Then, the consistency ratio

where

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.00 | 0.00 | 0.52 | 0.89 | 1.11 | 1.25 | 1.35 | 1.40 | 1.45 | 1.49 |

Table 2.

Average random consistency index [41].

If the value of

After this brief explanation about the AHP theory, in the next section, we will present the methodology developed for sizing batteries and show the approach developed for the application of the AHP method, which uses some of the information obtained through sizing.

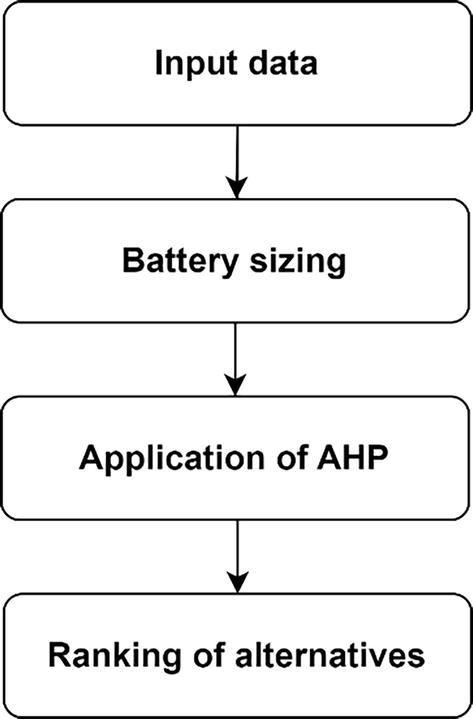

3. Approach developed for the application of the AHP method

In order to fulfill the objective of listing the battery alternatives, the “Input data” stage concerns the collection of essential data for the other calculations, originating from the region where the battery bank will be allocated, the demand, the conditions of use of the application, and the information provided by the manufacturers. In the dimensioning stage, the application data are combined with the data provided by the manufacturers, and the results of this stage alone provide a range of information on the different batteries evaluated, some of which will serve as input for the AHP method. In the “Application of the AHP method” stage, the batteries are classified according to each of the considered criteria and subcriteria. As a result, AHP lists battery alternatives in a priority ranking (Figure 2).

Figure 2.

Overview of the developed methodology.

3.1 Input data of the problem

One of the objectives of this work is the classification of different battery technologies to form a bank that meets a certain demand. Since this ordering is established considering the preference of certain qualification criteria. Therefore, input data are necessary for the development of the methodology, namely:

average temperature of the region: provided in C°, being necessary for calculating the time of use of the batteries;

energy demand: supplied in kWh, used to calculate the energy of the battery bank in the sizing.

operating regime: in this regard, we provide the period considered (hours, days, etc.), number of cycles per period, and the duration of each cycle per hour, and this information is used to determine the time of use of the battery bank.

battery database: these are made available by the manufacturers and used in the sizing calculation.

3.2 Battery sizing

In the methodology developed for dimensioning the batteries, the application data entered by the user and the information contained in the database are combined. The variables that make up the sizing are gravimetric density, volumetric density, optimal Depth of Discharge (DOD), battery bank energy, number of containers, and battery usage time. Determining the sizing variables provides the user with a range of information on the different battery alternatives evaluated, and some of this information serves as input for the AHP method.

Therefore, the design calculation was divided into six steps, as shown in the following algorithm. In Step 1, we described the calculation of gravimetric energy density. In Step 2, we present the calculation of the volumetric energy density. In Step 3, we show the methodology adopted to determine the optimal DOD. The calculation for energy from the battery bank is performed in Step 4. In Step 5, we establish the logic for defining the number of containers for storing the battery bank, taking two options for containers with volumes of

Battery sizing algorithm

G

End For

End For

Calculate the

Else

End If

End For

End For

End For

End For

3.3 Application of AHP

The methodology developed was divided into four phases: (i) definition of alternatives, (ii) definition of criteria and subcriteria, (iii) pairwise comparison and consistency check, and (iv) final classification. The methodology for phases (i) to (iii) is presented in this section. Phase (iv) consists of the calculations for prioritizing the alternatives and final classification, and these results are presented in Chapter 4.

3.3.1 Definition of battery alternatives

For the developed approach, four types of battery technologies were chosen, according to Table 3.

| N° | Battery alternatives | Manufacturer | Model |

|---|---|---|---|

| 1 | Ventilated Stationary Tubular Lead Acid (OPzS) | Fulguris | 3OPzs150 |

| 2 | Lead-Carbon Acid (PbC) | Narada | 12RECX120 |

| 3 | Ventilated Stationary Lead Acid | Moura Clean | 12MF175 |

| 4 | Lithium-Ion LFP (Iron Phosphate) | UniPower | UP-LFP 4875 |

Table 3.

Battery technology alternatives.

Batteries 1, 2, and 3 are lead-acid, one of the most used and developed technologies in the world. It has a low acquisition, installation, and maintenance cost and competes with lithium-ion batteries when weight and volume are not decisive factors. These batteries have the following characteristics: fast response time, low percentage of self-discharge, fully recyclable, presenting risks of corrosion, exposure to toxic agents, leakage, and potential for contamination. However, there are still limitations such as energy density and malfunction at low temperatures [42].

Battery 4 is iron phosphate lithium ion, and this technology features low weight, good storage capacity, absence of memory effect, high energy density, risk of explosion, exposure to toxic agents, contamination by lithium, phosphorus, and organic solvents [43].

3.3.2 Definition of criteria and subcriteria

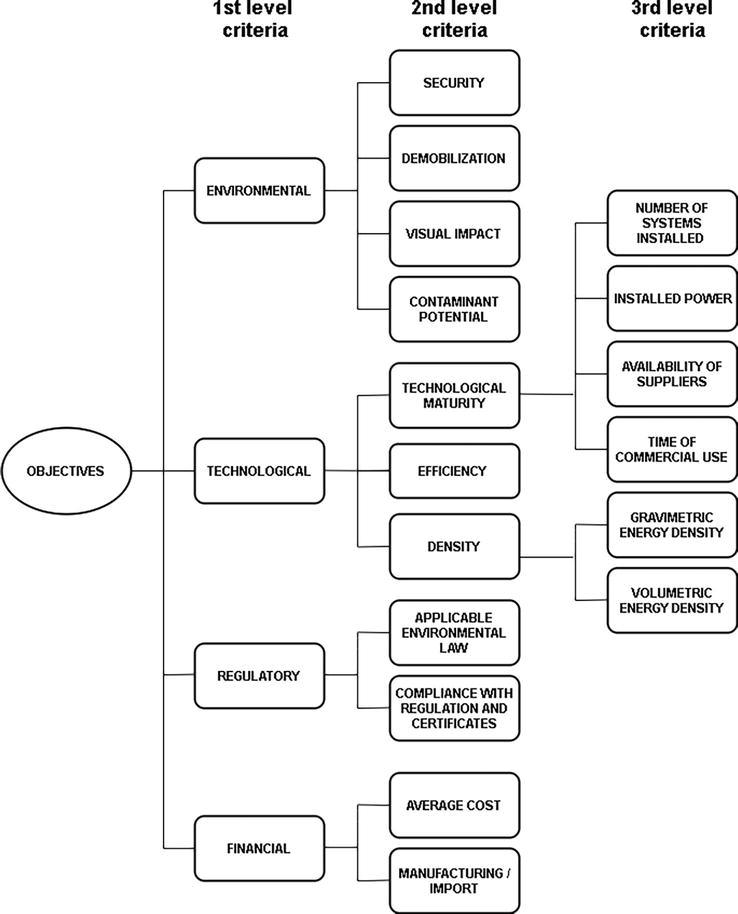

Based on previous studies and the experience of the researchers who developed this work, four criteria were defined for choosing battery alternatives, namely: environmental, technological, regulatory and financial, and subcriteria were also defined according to Figure 3. The main idea for these criteria is to consider different aspects that can influence this type of decision-making. Accordingly, a breakdown of the criteria and subcriteria is provided below.

Figure 3.

Hierarchical structure of the problem criteria.

3.3.2.1 EC environmental criteria

3.3.2.2 TC. Technological criteria

TC1. Technological Maturity

3.3.2.3 TC3. Density

3.3.2.4 RC. Regulatory criteria

3.3.2.5 FC. Financial criteria

With the exception of the security and density subcriteria, we can associate ranges of importance to each subcriteria according to Table 4. Note that if the average cost subcriterion does not have a budgeted value, studies can be used to estimate this value, adopting the importance ranges defined in Table 4.

| Subcriteria | Feature evaluated | Small | Great | Very large | Absolute |

|---|---|---|---|---|---|

| EC2 | Recycling | Disposable | Partially recycling | Fully recycling | — |

| ec3 | Number of containers | More than 2 type II containers | 2 type II containers | 1 type II containers | 2 type I containers |

| EC4 | Damage to the biota | Very serious | Serious | Average | Little |

| TC11 | Projects in the world | [0,10[ | [10,40[ | [40,80[ | |

| TC12 | Energy (MW) | [0,10[ | [10,50[ | [50,100[ | |

| TC13 | Number of suppliers in the world | [0,5[ | [5,20[ | [20,40[ | |

| TC14 | Usage time worldwide (years) | [0,10[ | [10,30[ | [30,60[ | |

| TC2 | Efficiency percentage | [0,0.8[ | [0.8,0.9[ | [0.9,0.95[ | |

| RC1 | Applicability of law | Not applicable | Law can be adapted | Established law but with difficult application | Established and applicable law |

| RC2 | Compliance with regulations and issuing of certificates | There is no norm and law | Is there a rule | There is rule and there is law | — |

| FC1 | Average cost | > 1000 | ]500,1000] | ]100,500] | |

| FC2 | Domestic or foreign manufacturing | Foreign | Domestic | Foreign | Domestic |

Table 4.

Level of importance per characteristic evaluated in each subcriterion.

3.3.3 Pairwise comparison and consistency check

After defining the alternatives and the hierarchical model of the problem, according to the AHP method, the pairwise comparisons begin to determine the level of importance between the criteria and subcriteria. For that, a questionnaire was developed with comparison matrices between the criteria and subcriteria, separated by type and level. For each comparison matrix, a pairwise evaluation must be performed using the Saaty scale (Table 1).

To carry out these evaluations, the questionnaire was sent to 12 professionals with degrees in the areas of Electrical, Environmental, Chemical, Materials, Forestry, in addition to the areas of Biology and Ecology.

From the responses of the questionnaire, the process of normalization and consistency of the scores is assigned by the specialists to validate the interdependence of the criteria and subcriteria (Section 2). The experts’ inconsistent assessments were dismissed. In sequence, to define the final weights to be used, we considered the geometric mean of the normalized scores of the eight specialists with consistent responses.

4. Numerical experiments

We performed numerical experiments for the problem of classifying different battery alternatives for energy storage in a region of Brazil, with an application demand of 50 kWh, two cycles of battery use per day, where each cycle lasts 10 hours, and also a temperature of 25C°.

4.1 Dimensioning of the chosen alternatives

Based on the input data of the problem, on the manufacturer’s catalog and the sizing methodology developed in Section 3, the characteristics of the batteries were obtained and calculated according to Table 5.

| Battery alternatives | Gravimetric energy density | Volumetric energy density | Optimal DOD (%) | Battery pack energy supplied | Containers number | Battery usage time (years) |

|---|---|---|---|---|---|---|

| 1 | 18.75 | 3.82E+04 | 54.43 | 91.9 | 1 of type I | 3.53 |

| 2 | 23.53 | 6.27E+04 | 25 | 200 | 1 of type I | 13.13 |

| 3 | 35.42 | 5.55E+04 | 20 | 250 | 1 of type I | 2.47 |

| 4 | 87.80 | 1.15E+05 | 64 | 78.12 | 1 of type I | 6.19 |

Table 5

Result of sizing battery alternatives.

4.2 Evaluation of the batteries according to the criteria

Through the results obtained in the dimensioning phase and also through the manufacturers’ data, in Table 6, we describe the results of each battery in relation to each criterion.

| Criteria | Battery 1 | Battery 2 | Battery 3 | Battery 4 |

|---|---|---|---|---|

| EC1 | 6 | 6 | 6 | 5 |

| EC2 | Recyclable | Recyclable | Recyclable | Disposable |

| EC3 | 1 container of type I | 1 container of type I | 1 container of type I | 1 container of type I |

| EC4 | Little damage | Serious damage | Average damage | Little damage |

| TC11 | 45 | 3 | 69 | 112 |

| TC12 | 61.4 | 1.0 | 61.4 | 174.6 |

| TC13 | [40,80[ | [5,20[ | [40,80[ | [40,80[ |

| TC14 | [10,30[ | [30,60[ | ||

| TC2 | 0.85 | 0.92 | 0.85 | 0.98 |

| TC31 | 0.01875 | 0.02353 | 0.03542 | 0.08780 |

| TC32 | 3.82E+04 | 6.27E+04 | 5.55E+04 | 1.15E+05 |

| RC1 | Law enacted and applicable to technology | Law can be adapted | Law enacted and applicable to technology | Law can be adapted |

| RC2 | Standard only | No standard | Standard only | Standard only |

| FC1 | ]500,1000] | ]500,1000] | ]500,1000] | |

| FC2 | Brazil | Abroad | Brazil | Abroad |

Table 6.

Characteristics of each battery regarding the criteria.

4.3 Application of the AHP method

To rank the different battery technologies, we use the AHP method. For this study, we considered two types of analysis. The first considers the view of specialists in the areas of engineering, environment, and chemistry regarding the analyzed criteria. The second considers theoretical cases where scenarios are generated considering the preference in each of the environmental, technological, regulatory, or financial criteria, and even a neutral scenario where all criteria have the same level of importance.

4.3.1 Expert scenario analysis

As presented in section 2, based on the consistent evaluations of the eight experts, the weights for each criterion and subcriteria were defined, according to Table 7. This set of weights was named Expert scenario.

| 1st level criteria | (%) | 2nd level criteria | (%) | 3nd level criteria | (%) |

|---|---|---|---|---|---|

| EC | 24.64 | EC1 | 37.39 | ||

| EC2 | 20.20 | ||||

| EC3 | 5.35 | ||||

| EC4 | 37.09 | ||||

| TC | 29.64 | TC1 | 19.04 | 12.92 | |

| 33.28 | |||||

| 37.07 | |||||

| 16.72 | |||||

| TC2 | 36.90 | ||||

| TC3 | 44.04 | 54.65 | |||

| 45.35 | |||||

| RC | 21.07 | RC1 | 51.67 | ||

| RC2 | 48.33 | ||||

| FC | 24.64 | FC1 | 61.45 | ||

| FC2 | 38.55 | ||||

Table 7

Weights for each criterion and subcriteria based on consistent expert responses.

Considering the weights defined by the expert’s answers (Table 7) and the weights defined through the ranges of interest (Table 4) together with the information of the batteries made available (Table 6), the final score of each heat in each criterion is provided in Table 8, and also the final priority of the heats.

| Battery | Environmental | Technological | Regulatory | Financial |

|---|---|---|---|---|

| 1 | 0.2371 | 0.1700 | ||

| 2 | 0.2371 | 0.1819 | 0.1186 | 0.2433 |

| 3 | 0.2527 | 0.2176 | ||

| 4 | 0.1985 | 0.1033 |

Table 8

Notes for each battery against the criteria.

From the perspective of the environmental criterion, the indicated technology is that of lithium ions; however, the difference between the results of the four technologies was not substantial. This alternative is also the most adequate regarding the technological criterion, in this case with a wide advantage in relation to the others. As for the regulatory and financial criteria, lead-acid (OpzS) and vented lead-acid batteries obtained the same results, since the two technologies have exactly the same input data for the associated subcriteria as show in Table 6.

Finally, with the assumptions adopted in this study and the four technologies evaluated, the final results are presented in Table 9. It appears that the overall result pointed to the Ventilated Stationary Lead-Acid technology as the best alternative for this study, that is, 27.92% priority over the others.

| Battery | Final priority | |

|---|---|---|

| 1 | Ventilated Stationary Tubular Lead Acid (OPzS) | 26.13% |

| 2 | Lead-Carbon Acid (PbC) | 19.73% |

| 3 | Ventilated Stationary Lead Acid | |

| 4 | Lithium Ion LFP (Iron Phosphate) | 26.22% |

Table 9

Final result of the AHP for each battery technology.

The results of the final priorities of technologies 1, 3, and 4 are very similar (around 2% off difference), so they can be considered technically equivalents and small changes in weights may result in different classifications.

4.3.2 Analysis of theoretical scenarios

With the AHP weights established, we can create other scenarios, which can explain different user preferences. For example, assuming a greater preference for a certain criterion and a lower weight for the others, or leaving them all with the same decision-making power, in this way the decision-maker indicates his priority.

To create these scenarios, we changed the weights given to the first-level criteria (Environmental, Technological, Regulatory, and Financial), while the rest of the weights are defined according to the expert’s scenario (Table 7).

In this way, we generate five different scenarios, namely: environmental, technological, regulatory, financial, and neutral. The weights for the criteria of each scenario can be seen below in Table 10, with the criterion with the highest weight highlighted in bold.

| Scenario | ||||||

|---|---|---|---|---|---|---|

| Environmental | Technological | Regulatory | Financial | Neutral | ||

| Criteria | EC | 0.2000 | 0.2000 | 0.2000 | ||

| TC | 0.2000 | 0.2000 | 0.2000 | |||

| RC | 0.2000 | 0.2000 | 0.2000 | |||

| FC | 0.2000 | 0.2000 | 0.2000 | |||

Table 10

Weights for the 1st level criteria in each scenario

Finally, considering the assumptions adopted in this study and the four technologies evaluated, Table 11 shows the final result of the AHP for each scenario. The general result presents the priority ranking of the batteries, with the Stationary Vented Lead-Acid technology being the best alternative for this application, among the four of the five analyzed scenarios. The evaluation of these scenarios is interesting to verify the performance of technologies considering different strategies.

| Battery | Scenarios priorities | ||||

|---|---|---|---|---|---|

| Environmental | Technological | Regulatory | Financial | Neutral | |

| 1 | 26.25% | 24.90% | 28.33% | 28.04% | 26.88% |

| 2 | 20.36% | 19.26% | 17.99% | 20.48% | 19.52% |

| 3 | 27.12% | ||||

| 4 | 25.57% | 24.08% | 22.18% | 25.14% | |

Table 11

Final AHP result for each battery technology in each scenario.

5. Conclusions

The Brazilian Power Sector is preparing the introduction of battery energy storage in its distribution lines for energy quality control. The success or failure of this new technology (from a financial and technical standpoint) depends on many factors. Different kinds of battery technologies have advantages and disadvantages depending on the operational systems regimes adopted. Different geographical locations, accessibility, spare parts availability, and other related factors may play a significant role in giving priority to one technology rather than another, and even environmental restrictions and the local regulatory framework can affect the results. The AHP algorithm is designed to take into account all these factors. It should be pointed out that the results depend a great deal on the evaluations of the specialists. In view of this, as many experts as possible must be consulted for each evaluated criteria and subcriteria to overcome this subjectivity.

In this work, we present a methodology to size and classify different battery alternatives, based on the AHP method. For this, considering the opinions of experts in the field, grades were assigned to different criteria and subcriteria, defined from the main characteristics of batteries in the segments: environmental, technological, regulatory, and financial.

Finally, to validate the developed methodology, we approach a problem of classifying four different types of battery technologies (Ventilated Stationary Tubular Lead Acid, Lead-Carbon Acid, Ventilated Stationary Lead Acid, and Lithium Ion LFP). In the study, two types of analysis were performed. The first analysis considered the specialists’ view about the analyzed criteria, and the study pointed out that the best alternative for the application was the Ventilated Stationary Lead-Acid battery.

The second analysis considered theoretical cases, with scenarios generated assuming a preference for each of the first-level criteria, and even a neutral scenario where all criteria have the same level of importance. In the results, the Ventilated Stationary Lead-Acid battery was the best alternative among the four of the five analyzed scenarios.

It is important to note that the useful life of the alternatives was used to calculate the batteries dimensioning; however, it was not considered as a criterion in the AHP method. In the future work, it is expected to use the useful life with the real prices of the technologies to replace the average price subcriteria.

The results of the method must be evaluated by specialists to validate the choice, since they have greater knowledge of the particularities of each technology. The advantage of using AHP for this problem is the consideration of subjective criteria such as environmental and regulatory criteria, which cannot be used directly in the calculation of the cost-benefit of technologies.

Acknowledgments

This research is been funding by R&D project PD-2866-0444/2016 proposed by Parana State Energy Company—Copel, under the auspices of the R&D Program of the Brazilian Electricity Regulatory Agency—ANEEL. The authors are also indebted to National Council for Scientific and Technological Development—CNPq for the subsidies for importation through law 8010/1990, I.I. 17/3098290-0.

References

- 1.

Barin A, Canha LN, Abaide AR, Magnago KF, Wottrich B, Machado RQ. Multiple criteria analysis for energy storage selection. Energy and Power Engineering. 2011; 3 (04):557 - 2.

Bueno A, Brandão C. Visão geral de tecnologia e mercado para os sistemas de armazenamento de energia elétrica no brasil. Associação Brasileira de Armazenamento e Qualidade de Energia. 2016; 1 :1-62 - 3.

Baumann M, Peters J, Weil M. Exploratory multicriteria decision analysis of utility-scale battery storage technologies for multiple grid services based on life-cycle approaches. Energy Technology. 2020; 8 :1-19 - 4.

Figgener J, Stenzel P, Kairies K-P k, Linßen J, Haberschusz D, Wessels O, et al. The development of stationary battery storage systems in Germany – A market review. Journal of Energy Storage. 2020; 29 :101153. DOI: 10.1016/j. est.2019.101153 - 5.

Bulut M, Özcan E. A novel approach towards evaluation of joint technology performances of battery energy storage system in a fuzzy environment. Journal of Energy Storage. 2021; 36 :102361. DOI: 10.1016/j.est.2021.102361 - 6.

Wu Y, Zhang T, Gao R, Wu C. Portfolio planning of renewable energy with energy storage technologies for different applications from electricity grid. Applied Energy. 2021; 287 :116562. DOI: 10.1016/j.apenergy.2021.116562 - 7.

Ahmadi SHR, Noorollahi Y, Ghanbari S, Ebrahimi M, Hosseini H, Foroozani A, Hajinezhad A. Hybrid fuzzy decision-making approach for wind-powered pumped storage power plant site selection: A case study. Sustainable Energy Technologies and Assessments. 2020; 42 :100838. DOI: 10.1016/j.seta.2020.100838.385 - 8.

Bohra SS, Anvari-Moghaddam A, Mohammadi-Ivatloo B. Ahp-assisted multi-criteria decision-making model for planning of microgrids. In: IECON 2019 - 45th Annual Conference of the IEEE Industrial Electronics Society. 2019. pp. 4557-4562. DOI: 10.1109/IECON.2019.8926887 - 9.

Nzotcha U, Kenfack J, Blanche Manjia M. Integrated multi-criteria decision making methodology for pumped hydro-energy storage plant site selection from a sustainable development perspective with an application. Renewable and Sustainable Energy Reviews. 2019; 112 :930-947. DOI: 10.1016/j.rser.2019.06.035 - 10.

Çelikbilek Y, Tüysüz F. An integrated grey based multi-criteria decision making approach for the evaluation of renewable energy sources. Energy. 2016; 115 :1246-1258. DOI: 10.1016/j.energy.2016.09.091 - 11.

Rojas-Zerpa JC, Yusta JM. Application of multicriteria decision methods for electric supply planning in rural and remote areas. Renewable and Sustainable Energy Reviews. 2015; 52 :557-571. DOI: 10.1016/j.rser.2015.07.139 - 12.

Aragonés-Beltrán P, Chaparro-González F, Pastor-Ferrando J-P, PlaRubio A. An ahp (analytic hierarchy process)/anp (analytic network process) based multi-criteria decision approach for the selection of solar-thermal power plant investment projects. Energy. 2014; 66 :222-238. DOI: 10.1016/j.energy.2013.12.016 - 13.

Liu Y, Du JL. A multi criteria decision support framework for renewable energy storage technology selection. Journal of Cleaner Production. 2020; 277 :122183. DOI: 10.1016/j. jclepro.2020.122183 - 14.

Zhao H, Guo S, Zhao H. Comprehensive performance assessment on various battery energy storage systems. Energies. 2020; 11 (10):2841. DOI: 10.3390/en11102841 - 15.

Li L, Liu P, Li Z, Wang X. A multi-objective optimization approach 415 for selection of energy storage systems. Computers & Chemical Engineering. 2018; 115 :213-225. DOI: 10.1016/j.compchemeng - 16.

B. Özkan, Íhsan Kaya, U. Cebeci, H. Ba ̧slıgil, A hybrid multicriteria decision making methodology based on type-2 fuzzy sets for selection among energy storage alternatives, International Journal of Computational Intelligence Systems 8 (5) (2015) 914–927. doi:10.1080/18756891.2015. - 17.

Saaty TL. A scaling method for priorities in hierarchical structures. Journal of Mathematical Psychology. 1977; 15 (3):234-281. DOI: 10.1016/0022-2496(77)90033-5 - 18.

Saaty TL. How to make a decision: The analytic hierarchy process. European Journal of Operational Research. 1990; 48 (1):9-26. DOI: 10.1016/0377-2217(90)90057-I - 19.

Kushal TRB, Illindala MS. A decision support framework for resilience-oriented cost-effective distributed generation expansion in power systems. In: 2020 IEEE/IAS 56th Industrial and Commercial Power Systems Technical Conference (I CPS). Las Vegas, USA. 2020. pp. 1-8. DOI: 10.1109/ICPS48389.2020.9176823.440 - 20.

Baumann M, Weil M, Peters JF, Chibeles-Martins N, Moniz AB. A review of multi-criteria decision making approaches for evaluating energy storage systems for grid applications. Renewable and Sustainable Energy Reviews. 2019; 107 :516-534. DOI: 10.1016/j.rser.2019.02.016 - 21.

Paul S, Nath AP, Rather ZH. A multi-objective planning framework for coordinated generation from offshore wind farm and battery energy storage system. IEEE Transactions on Sustainable Energy. 2020; 11 (4):2087-2097. DOI: 10.1109/TSTE.2019.2950310 - 22.

Waewsak J, Ali S, Natee W, Kongruang C, Chancham C, Gagnon Y. Assessment of hybrid, firm renewable energy-based power plants: Application in the southernmost region of Thailand. Renewable and Sustainable Energy Reviews. 2020; 130 :109953. DOI: 10.1016/j.rser.2020.109953 - 23.

Liu J, Yin Y, Yan S. Research on clean energy power generation-energy storage-energy using virtual enterprise risk assessment based on fuzzy analytic hierarchy process in China. Journal of Cleaner Production. 2019; 236 :117471. DOI: 10.1016/j.jclepro.2019.06.302 - 24.

Jiang T, Li X, Chen H, Zhang R, Li G, Kou X, et al. Optimal energy storage siting and sizing to mitigate voltage deviation in distribution networks, in. IEEE Power Energy Society General Meeting (PESGM). 2019; 2019 :1-5. DOI: 10.1109/PESGM40551.2019.8973500 - 25.

Al-Madhlom Q, Al-Ansari N, Laue J, Nordell B, Hussain HM. Site selection of aquifer thermal energy storage systems in shallow groundwater conditions. Water. 2019; 11 (7):1393 - 26.

Solangi YA, Longsheng C, Shah SAA. Assessing and overcoming the renewable energy barriers for sustainable development in Pakistan: An integrated ahp and fuzzy topsis approach. Renewable Energy. 2021; 173 :209-222 - 27.

Zanakis SH, Solomon A, Wishart N, Dublish S. Multi-attribute decision making: A simulation comparison of select methods. European Journal of Operational Research. 1998; 107 (3):507-529. DOI: 10.1016/S0377-2217(97)00147-1 - 28.

Daim T, Yates D, Peng Y, Jimenez B. Technology assessment for clean energy technologies: The case of the pacific northwest. Technology in Society. 2009; 31 (3):232-243. DOI: 10.1016/j.techsoc.2009.03.009 - 29.

Yuan X-C, Lyu Y-J, Wang B, Liu Q-H, Wu Q. China’s energy transition strategy at the city level: The role of renewable energy. Journal of Cleaner Production. 2018; 205 :980-986. DOI: 10.1016/475j.jclepro.2018.09.162 - 30.

Luthra S, Kumar S, Garg D, Haleem A. Barriers to renewable/sustainable energy technologies adoption: Indian perspective. Renewable and Sustainable Energy Reviews. 2015; 41 :762-776. DOI: 10.1016/j.rser.2014.08.077 - 31.

Cowan K, Daim T, Anderson T. Exploring the impact of technology development and adoption for sustainable hydroelectric power and storage technologies in the pacific northwest united states. Energy. 2010; 35 :4771-4779. DOI: 10.1016/j.energy.2010.09.013 - 32.

Ben Ammar F, Hafsa IH, Hammami F. Analytic hierarchy process selection for batteries storage technologies. In: 2013 International Conference on Electrical Engineering and Software Applications. Hammamet, Tunsia. 2013. pp. 1-6. DOI: 10.1109/ICEESA.2013.6578374 - 33.

Walker SB, Mukherjee U, Fowler M, Elkamel A. Benchmarking and selection of power-to-gas utilizing electrolytic hydrogen as an energy storage alternative. International Journal of Hydrogen Energy. 2016; 41 :7717-7731. DOI: 10.1016/j.ijhydene.2015.09.008 - 34.

Ayodele T, Ogunjuyigbe A, Odigie O, Munda J. A multi-criteria gis based model for wind farm site selection using interval type-2 fuzzy analytic hierarchy process: The case study of Nigeria. Applied Energy. 2018; 228 :1853-1869. DOI: 10.1016/j.apenergy.2018.07.051 - 35.

Wu B, Yip TL, Xie L, Wang Y. A fuzzy-madm based approach for site selection of offshore wind farm in busy waterways in China. Ocean Engineering. 2018; 168 :121-132. DOI: 10.1016/j.oceaneng.2018.08.065 - 36.

Ali S, Taweekun J, Techato K, Waewsak J, Gyawali S. Gisbased site suitability assessment for wind and solar farms in Songkhla, Thailand. Renewable Energy. 2019; 132 :1360-1372. DOI: 10.1016/j.renene.2018.09.035 - 37.

Uyan M. Gis-based solar farms site selection using analytic hierarchy process (ahp) in Karapinar region, Konya/Turkey. Renewable and Sustainable Energy Reviews. 2013; 28 :11-17. DOI: 10.1016/j.rser.2013.07 - 38.

Wang Q, Han R, Huang Q, Hao J, Lv N, Li T, et al. Research on energy conservation and emissions reduction based on ahp-fuzzy synthetic evaluation model: A case study of tobacco enterprises. Journal of Cleaner Production. 2018; 201 :88-97. DOI: 10.1016/j.jclepro.2018.07.270 - 39.

How BS, Yeoh TT, Tan TK, Chong KH, Ganga D, Lam HL. Debottlenecking of sustainability performance for integrated biomass supply chain: P-graph approach. Journal of Cleaner Production. 2018; 193 :720-733. DOI: 10.1016/j.jclepro.2018.04.240.525 - 40.

Ma Y, Shi T, Zhang W, Hao Y, Huang J, Lin Y. Comprehensive policy evaluation of nev development in China, Japan, the United States, and Germany based on the ahp-ew model. Journal of Cleaner Production. 2019; 214 :389-402. DOI: 10.1016/j.jclepro.2018.12.119 - 41.

Saaty TL, Vargas LG. How to make a decision. Models, Methods, Concepts and Applications of the Analytic Hierarchy Process. Springer; 2012; 175 :23-40. DOI: 10.1007/978-1- 4614-3597-6 - 42.

Luo X, Wang J, Dooner M, Clarke J. Overview of current development in electrical energy storage technologies and the application potential in power system operation. Applied Energy. 2015; 137 :511-536. DOI: 10.1016/j.apenergy.2014.09.081 - 43.

Ferreira JH, Tavares C. Desenvolvimento, implementação e simulação de um controlador para sistemas de armazenamento de energia com baterias [thesis]. Porto, Portugal: University of Porto; 2015 - 44.

Huff G. DOE Global Energy Storage Database. Albuquerque, NM (United States): Sandia National Lab; 2015