Effects of by-products cereal addition in different products.

Abstract

Cereals represent one the most famous crops worldwide, covering more than 20% of the human daily diet. Through their processing, several agro-food chain by-products are generated, emphasizing an urgent need for further valorization considering economic, social, and environmental factors. The ever-increasing demand for food requires new, healthy, and sustainable products. Therefore, the present chapter aims to highlight the main possibilities for cereal by-products valorization in bakery, pastry, and gastronomy products. Fermentation of the cereal by-products with lactic acid bacteria, optimization of the added by-product percentages in new functional products, extrusion process, and food fortification will be the main topics of the proposed chapter. The influence of the cereal by-products addition on human health will be also discussed.

Keywords

- cereals

- by-products

- fermentation

- lactic acid bacteria

- extrusion

- anti-nutrients

- bioactive compounds

1. Introduction

Cereals are the main worldwide crop with a planting area of more than 73% of the total global harvested area [1]. The term ‘cereals’ includes nine

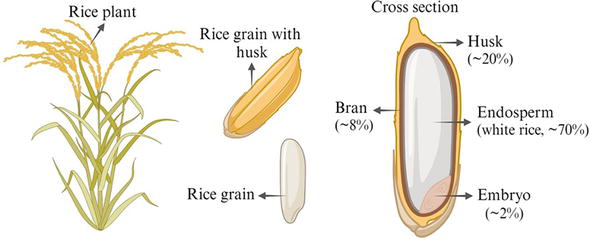

Figure 1.

Rice plant and cross section of the rice grain.

Wheat, rice, and maize are the main contributors to the 12% increasement of the global food production till 2025 as indicated by Food and Agriculture Organization (FAO) statistics, [4]. In line with this, Fărcaș et al. [5] stated that more than 90% of cereal consumption is represented by rice, wheat, barley, and maize. From 2008 to 2016, the annual worldwide production of cereals averaged around 3200 million tons, encompassing grains such as wheat, maize, sorghum, barley, rice, oat, rye, and millet [6]. During 2020–2021, the worldwide cereal production was formed mainly of corn, with a percentage of 42%, wheat 29%, and rice and barley with values of 19% and 6%, respectively [7].

Cereal grains have been a fundamental element of the human diet for millennia. Their processing is a crucial aspect of the food production chain, involving a complex process such as dry milling (for wheat and rye), pearling (for rice, oat, and barley), wet milling (for corn and wheat), and malting (for barley, corn, and wheat), [6]. In the process of dry milling, the outer fibrous materials and germ are separated, resulting in by-products of the grain endosperm, whilst pearling is a dry milling abrasive technique that systematically eliminates the seed coat (testa and pericarp), aleurone and subaleurone layers, as well as the germ, to achieve polished grain (as seen in rice, oat, and barley), along with by-products containing a high concentration of bioactive compounds [2].

Conversely, wet milling is primarily employed in the manufacturing of starch and gluten, generating steep solids (abundant in nutrients valuable for the pharmaceutical industry), germ (utilized in the oil-crushing industry), and bran as by-products. Malting, designed for the production of beer and other alcoholic beverages, involves the consumption of fermentable sugars and starch in the grain (typically barley) by enzymes, resulting in a by-product entitled spent grain [2].

Throughout cereal processing, by-products with distinct physical states and chemical compositions are simultaneously generated [6]. Globally, approximately 12.9% of total food waste is produced through cereal processing [5], Europe and North America claiming a total cereal food chain loss production between 10 and 12%, meantime, Asia recorded a percentage of up to 18% [8]. Only in Europe, the total amount of cereal waste is approximately 40,000–45,000 tons/year [8].

The cereal milling has as the main objective the flour manufacturing and generates various by-products such as bran, hull, germ, husk, fiber, protein, and broken grains [6]. The cereals bran and germ fractions, also coined the “dark matter of nutrition” are abundant in vitamins, minerals, dietary fiber, and thousands of phytochemicals [9].

Bran is the main by-product generated from the cereal milling process and typically refers to the outer layers of the grain. Its composition is highly variable and influenced by factors such as grain type, kernel size, shape, maturity, germ size, pericarp thickness, grain storage duration and condition, pre-milling grain conditioning, milling process, and the machinery employed during milling [3]. The percentage of the bran obtained after wheat milling is about 15%, whilst, the barley yield of milling by-products is estimated to be around 30–40% [3]. With respect to wheat, given that over 650 million tons are produced and processed annually, the associated quantity of wheat bran was approximated to be 150 million tons per year [10].

On the other side, the processing of rough rice, undertaken to produce milled edible rice commonly known as white rice, results in by-products, namely rice hull (constituting 20% of rough rice) and rice bran and germ (making up 10% of rough rice), [8].

The dry milling maize process led to the production of maize bran fraction and further to maize germ, a by-product used in the oil production, whilst, wet maize milling generates by-products such as maize fiber and maize protein [11]. Maize germ represents 10–12% of the whole corn kernel, meantime, corn bran could be varied from 5 to 6% [12]. Nowadays, there is an increasing interest for the bakery companies to use maize flour in product manufacturing, therefore, the maize bran demand is highly increasing [11].

Apart from the dry milling maize process, the barley malting process led to spent malt rootlets by-product generation, meantime, the beer manufacturing process produced a huge amount of brewer spent grain, spent hops, and surplus yeast [7].

Therefore, considering that the main worldwide crops are corn, wheat, rice, and barley, the chapter will characterize the chemical composition of the main by-products generated after selected cereals processing. Afterward, it will emphasize modern strategies to increase the bioaccessibility of bioactive compounds, show their further use in the manufacturing of bakery, pastry, and gastronomy products, and review the main positive influences on human health.

2. General composition and bioactive compounds in cereal by-products

Wheat bran is a rich source mainly in carbohydrates, with an amount more than 57% (from which starch, hemicelluloses, and cellulose are the main representants), protein in a range between 13 and 18%, lipids: 3–4%, 3–8% ash, [10], dietary fiber along with a diverse array of biologically active compounds, including alkylresorcinol, ferulic acid, β-glucan (ranging from 22 to 27 g/100 g dry weight), and arabinoxylan (ranging from 22.4 to 29.80 g/100 g dry weight) [7]. Wheat bran and oat bran contain a high amount of phenolic acids such as 4527 and 4190 μg/g, respectively [1]. Wheat germ has a lipid composition in a range of 10–15 g/100 g dry weight, protein amount between 26 and 35 mg/100 g dry weight, fiber with values between 15 and 45 g/100 g dry weight as well as bioactive compounds such as thiamin, riboflavin, tocopherols, but also phytosterols and carotenoids [7].

With respect to corn bran’s chemical composition, it contains 10–13% proteins, lipids (2–3%), starch (9–23%), 2% ash, and a high amount of dietary fiber (76–90%), [8, 13]. Typically, corn bran contains various phenolic acids, with ferulic acid being the primary one, but also vanillic, caffeic, p-coumaric, and p-hydroxybenzoic acids have been identified in significant amounts [8].

On the other hand, rice bran (composed of bran layer and rice germ) is a good source of fatty acids, minerals, dietary fibers, protein, and several phytochemical compounds, claimed to play a significant role in biological activities such as antioxidants or anti-inflammation [14]. It is mainly composed of carbohydrates in a range between 30 and 50%, lipids in a higher amount compared with wheat bran (up to 19%), and protein around 14% [10]. The results are in line with Sapwarobol et al., [15] who mentioned a 50% carbohydrate level, fat in an amount of 20%, protein 15%, and dietary fiber. The bran derived from brown rice is recognized for its prebiotic potential, it contains beneficial compounds such as dietary fibers, essential fatty acids, polyphenols, and antioxidants [11]. Rice bran is considered to have antioxidative, hypocholesterolemic, and hypoallergenic properties, being an important source of nutrients. On the other side, black rice contains a better amount of minerals, higher amino acids amount, and phytochemicals compared to the white rice. Black rice germ and bran contain flavonoids, vitamin E, and γ- oryzanol with positive benefits such as anti-inflammatory and antioxidants characteristics [14].

Additionally, it is important to mention the rich chemical composition of the main by-products from the beer manufacturing and barley malting processes such as brewer spent grain and spent malt rootlets, respectively. Brewer spent grain is claimed by the literature as having high fiber amount (up to 70%), protein in a range between 25 and 30%, and lipid up to 10% [10]. It has a big advantage of being available throughout the whole year, at a low or no cost, and being produced in large amounts by industrial or small breweries [16]. Brewer spent grain is a rich source of phenolic compounds, mainly caffeic,

Spent malt rootlets are a rich source of protein (35 g/100 g), a source of minerals (total ash 5.98 g/100 g), total fiber (36.64 g/100 g) and soluble fiber (1.24 g/100 g), [21], and represents the main by-products generated during the barley malting process. Spent malt rootlets represent 5% of the total malt weight [21] and it is a rich source of essential and non-essential amino acids, phenolic compounds, mono and di-saccharides sugars, and insoluble dietary fiber [22]. Spent malt rootlets are rich in ferulic and p-coumaric acids, being a natural source of antioxidants [23]. Moreover, it is a rich source of macrominerals such as Ca (0.19%), P (phosphorus) (0.69%), Mg (0.17%), and K (1.17%) and microminerals such as zinc (Zn), manganese (Mn), and copper (Cu) with values of 64 ppm, 36 ppm, and 9 ppm, respectively [24]. It is worth also mentioning its rich composition in vitamin E, B group vitamins, and peptides [25].

3. Advancements in nutrient bioaccessibility of cereal by-products

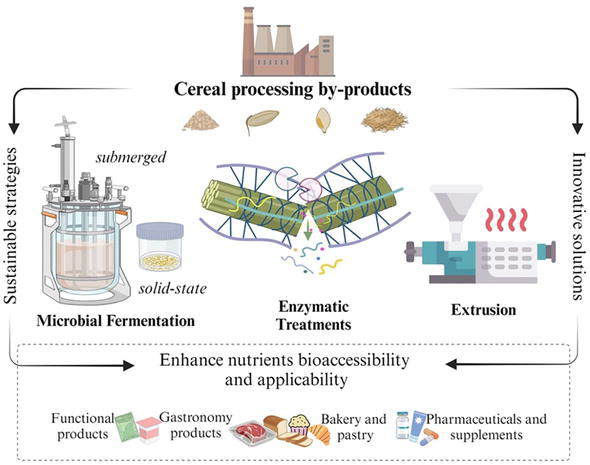

This part of the chapter will go over the main methods used for increasing bioaccessibility and bioavailability of cereal bioactive compounds, as presented in Figure 2. Fermentation processes with lactic acid bacteria (the submerged and the solid-state), enzymatic treatments, and extrusion will be the main discussed topics. The cereal processing industry is actively seeking alternative methods to reduce the generation of by-products and waste.

Figure 2.

Pre-treatments used for cereal processing by-products.

Consequently, several efforts are being made to explore innovative solutions and applications for the valorization of these by-products. This involves their reprocessing to extract valuable compounds or undergo chemical, microbiological, and enzymatic conversions [11] together with their reuse in different food manufacturing processes.

Unfortunately, flours with high bran content produce final baked goods with poor loaf volume, dense texture, bitter taste, and dark color [26]. The negative properties of bran wheat on the final baked product are mainly due to the interaction between gluten and other bran components such as antioxidants, phenolics, dietary fiber, and enzymes [27]. On the other hand, it seems that also bran particle size or even water absorption capacity together with the fiber water competition could produce an insufficient hydration of starch and gluten that could negatively influence the wheat bran characteristics [27, 28]. Brewer spent grain is another cereal by-product generated during beer manufacturing that still has a limited exploitation as food raw materials mainly because of its poor technological properties, low sensory performance, and astringent flavor [28].

From the nutritional point of view, cereal bran bioactive compound has a low bioaccesibilty and bioavailability. Bioaccesibility is defined as the release amount of bioactive compounds before their absorption in the small intestine, while bioavailability refers to the amount of bioactive compounds that could be rich into the blood flow, organs, and different tissues [19].

Generally, the low phenolic acids and dietary fibers’ low bioaccesibilty are due to their entrapping in the cell wall structures. Moreover, the cereal proteins’ bioavailability is limited to several factors such as the presence of antinutritional phytate-protein complexes and the layers’ structure mainly formed of insoluble carbohydrates and lignin [29]. Furthermore, compounds such as phytic acid or tannins are present in the cereal outermost tissues being recognized as anti-nutritive compounds [30]. It is already known that phytate forms complexes with minerals present in cereals and seeds, leading to reduced solubility, absorption, and digestibility of minerals. This consequently lowers the bioavailability of these compounds [31]. Moreover, phytic acid content of wheat which could vary in a range between 5.4–8.4% might even reduce the protein nutritional value by absorbing bivalent ions such as Ca2+, Zn2+, Mg2+, or Fe2+, respectively [32].

To overcome this challenge, new milling methods, and new pretreatments such as fermentation and enzymatic ones are highly required to enhance the bran cereal’s nutritional potential [29]. Bioprocessing of bran could represent a useful tool and refer to the exploitation of the biological activity exhibited by cells or their components, including microbes and enzymes [33]. In line with this, Hartikainen et al., [33] stated that the use of a big percentage addition of bran wheat in bakery products manufacturing could negatively affect the rheological properties of the dough such as the free expansion, that could further affect the final baked product volume. Moreover, the gluten structure will be affected due to bran action against aggregation of gluten proteins and the bran addition could accelerate the bread staling process [33].

Significant research has investigated the use of lactic acid bacteria to enhance the value of cereal by-products. For instance, rice bran fermented with

Another tool to enrich the chemical composition of cereal by-products is the use of enzymes. Enzymatic treatments offer an alternative approach to mitigate the adverse effects of conventional extraction methods, which typically involve chemical degradation or disruption of cell wall plant matrices through acid or base hydrolysis. This alternative method aims to improve the extractability yield and antioxidant activity of phenolics [11]. Enzymes could increase the bioavailability of ferulic acid. For instance, esterase is able to release ferulic acid from fiber complex in both human and rat intestinal mucosa [31]. In line with this, a sustainable method for brewer spent grain ferulic acid extraction is the use of enzymatic hydrolysis with feruloyl esterase. The enzymatic process has several advantages such as higher extraction yields, environmentally friendly, and process scalability [36]. Ferulic acid recovery from brewer spent grain could be significantly improved through an optimum enzyme dosage, optimization of the incubation time, and parameters such as temperature and pH [36].

Enzymatic hydrolysis is a well-known method used to overcome the insolubility of brewer spent grain protein, with no negative effect on the amino acids chain [37]. Recently, Bazsefidpar et al. [37] showed that the main drawbacks of brewer spent grain such as the low protein solubility or color, could be improved through using different enzyme proteases such as flavoenzyme, alcalase, papain, or pancreatin obtained from different sources such as fungal, bacterial, plants, or even animals.

The bioprocessing of wheat bran through fermentation with

On the other side, solid-state fermentation with

Two mesophilic solid-state fermentations of brewer spent grain were successfully used to enrich the nitrogen content and suggested there is a strong connection between the native microbiota and the inoculated one. A combination of yeasts (

In the fermentation process of rice bran with

A big disadvantage of the fermentation process claimed by the literature is the long time process to achieve the desired bioactive compounds concentration together with the use of batch reactors in which the undesirable microorganism could develop [44]. Moreover, the cost needed for stirring or aeration during the conventional fermentation process is relatively high [45]. On the other side, the same issues were identified in solid-state fermentation, mentioning that there is less energy input due to the lower liquid phase and less operational costs such as aeration or stirring but there are some difficulties in monitoring temperature, humidity, and pH values [45].

To overcome this challenge, the extrusion process is claimed by a large body of literature as being a technological solution that combines short time, high temperature with pressure under a shear force, triggering molecular disruption, and leading to textural and structural changes in the raw materials [44, 46].

A hypothesis was formulated suggesting that the solubility of dietary fiber might be enhanced through extrusion cooking, likely attributed to the decrease in particle sizes of extruded samples and/or the disruption of covalent and non-covalent bonds in larger molecules resulting from the application of high temperatures [11]. This is in line with the finding of Grasso [47] who mentioned that the extrusion process could alter the molecular fiber structure and increase the soluble fiber amount and with Aktas-Akyildiz et al., [48] who showed that extrusion parameters are highly important in the increment of wheat bran fiber solubility together with enzymatic hydrolysis that could successfully further extend the dietary fiber solubility.

Accordingly, Haghighi-Manesh et al., [49] showed that extrusion and enzymatic treatments have a synergetic effect leading to a higher corn bran soluble dietary fiber. In line with this, extrusion process parameters (temperature 130°C, feed moisture 24%, and screw speed 400 rpm) of wheat bran increased the extractability of total dietary fiber with 40%, whilst arabinoxylan extractability increased from 5.8 to 9% [44]. Rice bran extrusion (temperature 100°C, feed moisture 60%, and 100 rpm) led to a total increase content of soluble fibers with 30% [44].

On the other side, extrusion cooking process enhanced the release of phenolic compounds and thermal processing of maize bran (160°C for 1 hour) allowed the solubilization of ferulic acid in a percentage of 80%, in the form of feruloylated oligosaccharides, that has higher antioxidant activity than free ferulic acid [50]. During extrusion of wheat bran feed moisture of 30°C followed by temperatures of 140 and 180°C highly improved the extraction yield of bound phenolic content [44]. The extrusion process of rice bran increased the phenolic bioaccessibility from 395.11 to 555.27 mg GAE/100 g, respectively [42].

The rice bran extrusion process improved its color, decreased the amount of phytic acid, and did not change the content of vitamins such as folic acid, niacin, pantothenic, or riboflavin amount. Likewise, a positive effect was observed in the amount of dietary fiber, which is involved in human constipation improvement [51]. Moreover, the use of rice bran in the starch-based extruded snacks is a tool for the improvement of the porous structure, increases the water holding capacity, retarded the starch retrogradation, and enhances the syneresis during storage of rice bran extruded snacks [52].

Another key role of the extrusion process is the capacity to inactivate enzymes such as lipases and lipoxygenases and therefore inhibit the cereal by-products post-milling rancidification [44].

4. Innovative applications in bakery, pastry, and gastronomy

Aspects of concern which have been investigated in various studies include the physical characteristics of by-products and the methods employed for their integration into new products. This involves preserving product stability, textural characteristics, and consumer acceptance while minimizing any adverse impact on the properties of the targeted compounds found in the cereal by-products. Therefore, the valorization of cereal by-products impact on the food chain with a focus on bakery, pastry, and gastronomy products will be further discussed in the present chapter.

The utilization of corn bran in the snack bar manufacturing was mentioned by Sousa et al., [53], who produced snack bars with a high percentage addition of corn bran (55%), resulting in a product with increased nutritional content in total dietary fiber (11.30 g/100 g), lower in carbohydrates (70.27 g/100 g) compared with the control (79.43 g/100 g) and higher in lipids (2.64 g/100 g). From the physical parameters point of view, the use of corn grain in a percentage of 55% influenced the increase of hardness value, from a value of 85.74 N (control sample) to a value of 126.26 N, respectively [53]. In this line, Grasso [47] showed that corn bran could be successfully used in extruded snacks manufacturing, with an inclusion range between 10 and 80%, resulting in enriched fiber corn extrudates.

Another study highlighted that the use of corn bran in cake batter manufacturing could be successful to a percentage addition of 20%, without negative effect on hardness, springiness, and accepted by consumers form the texture, taste, and overall acceptability attributes [13]. Sharma et al., [54] mentioned that blending of corn bran, defatted corn germ, and corn gluten with wheat flour increases the protein, minerals (Ca, P, and Fe), and crude fiber content and the effect of blending in bread, muffins, cookies, noodles, and extruded snacks is presented in Table 1.

| By-products | New product | Maximum addition | Improvement on the final product |

|---|---|---|---|

| Bakery and pastry products | |||

| Corn bran | Snack bars | 55% | ↑ of dietary fiber, ↑ lipid content, and ↑ mineral content, [53] |

| Corn bar | Extruded snacks | 10–80% | ↑ total dietary fiber content [47] |

| Corn bran | Cake batters | 20% | ↑ dietary fiber, hardness and springiness not affected, and accepted by consumers [13] |

| Corn bran, defatted germ and gluten | Noodles and extruded snacks | 10% | ↑ cooking time; ↑ water absorption ratio; and gluten blended snacks ↑ overall acceptability |

| Corn bran, defatted germ and gluten | Bread, cookies, and muffins | 5–10% | ↑ volume bread made with corn gluten; corn germ muffins ↑ acceptability scores; |

| Fermented wheat bran | Wheat bran | 20% | ↑ fiber (arabinoxylans) solubilization [33] |

| Fermented wheat bran and enzyme treatment | Wheat bran | 20% | Hardness and volume improved [33] |

| Wheat bran | Extrudates | 10–20% | ↑ soluble dietary fiber; ↓ insoluble fiber content [47] |

| Corn bran | Functional cake | 5–10% | ↑ soluble dietary fiber; ↑ desirable sensorial properties; and ↑ textural properties (↓cohesiveness and springiness, ↑ gumminess), [49] |

| Wheat bran | Tafton bread | 15% | ↑ soluble dietary fiber; ↑ freshness and shelf-life [32] |

| Wheat bran pre-fermented and enzyme treatment | Bread | ↑ arabinoxylan solubility in the dough; ↑dough rheological characteristics; and ↑quality of bread [55] | |

| Wheat bran fermented | Steamed bread | 3–9% | ↑ bread resilience; ↑bread specific volume; [56] |

| Rice bran fermented | Gluten-free cookies | 7.08% | ↑ protein level; ↑phenolic compounds; ↑ antioxidant activity; and ↑shelf-life [57]. |

| Defatted rice bran | Bread | 5–10% | ↑ dietary fiber content; ↑ antioxidant activity and shelf-life [58] |

| Spent malt rootlets fermented | Steamed bread | 5% | ↑ specific volume; ↑crumb softness; and ↑ bread flavors [21]. |

| Spent malt rootlets fermented | Bread | 15% | ↑ specific volume; ↓ crumb hardness; limited microbial growth rate; and ↓ the release of sugar during digestion [59] |

| Spent malt rootles | Multigrain biscuits | 15% | ↑ fatty acid content; ↑ volatile compound; and ↑ sensorial characteristics [60] |

| Brewer spent grain | Muffins | 6% | ↑ antioxidant activity; ↓ peroxide and thiobarbituric acid [61] |

| Brewer spent grain | Bread | 10% | ↑ protein, mineral, and dietary fiber [62] |

| Brewer spent grain | Breadsticks | 15–35% | ↑ dietary fiber content and protein; ↓ crispiness; and ↓ lower baking volume [63] |

| Brewer spent grain | Bread | 20–25% | ↑ phenolic content; ↑ soluble and insoluble fiber; ↓ bread texture; and ↑ hardness [64] |

| Brewer spent grain | Bread | 5–20% | ↑ mineral, protein, fiber, and fat [65]. |

| Brewer spent grain | Dry pasta | 10 g/100 g | ↑ protein, dietary fiber, antioxidant activity, and β-Glucan [66] |

| Wheat bran | Chicken meat biscuits | 5% | ↑ oxidative stability; ↑ crude fiber and ash contents [67] |

| Wheat bran extract | Beef meat hamburgers | 0.8% | ↓ the formation of oxidation products; ↑antioxidant potential [68] |

| Wheat bran | Meatballs | 5–20% | ↓ total fat content; ↓ total |

| Corn bran | Turkish meatballs | 10–15% | ↓ weight losses; ↑ protein content; and ↑ fiber amount [70] |

| Brewer spent grain | Bratwurst sausage | 3% | ↑ protein content; ↑ color, chewiness, appearance, and pastiness [71] |

| Brewer spent grain | Chicken patties | 3% | ↑ dietary fiber; improve the cooking loss [72] |

| Brewer spent grain | Smoked sausages | 3% | ↑protein, ash; ↑ freshness [73] |

| Brewer spent grain | Beef frankfurters | 1–5% | ↑ total dietary fiber [74] |

| Spent malt rootles | Sausage | 10% | ↓ cooking losses; ↑ fiber content [22] |

Table 1.

↑ increase; ↓ decrease.

Milled corn bran was previously submitted to an integrated extrusion-enzymatic treatment and afterward, included in a functional cake manufacturing process. An addition of 30% pretreated corn bran was considered too much for the panelist’s textural and taste points of view, meantime, a 10% addition was the optimum percentage [49] that accomplished the general panelist expectations.

The use of wheat bran fermented with yeast and its 20% addition in bread manufacturing process positively influenced the protein (21.8%), soluble arabinoxylans (1.6%), and ash (6.6%) contents, while the enzyme-assisted yeast fermentation of bread wheat mainly improved soluble arabinoxylans content (3.8%) [33]. Tafton bread is a consumed product in Iran [32] and wheat bran fermented by

The addition of 7.08% rice bran fermented with

Spent malt rootlets fermentation with different lactic acid bacteria such as

Biscuits are considered popular products which nowadays are nutritionally deficient in some nutrients such as minerals, protein, and even dietary fiber [60]. The utilization of a 15% addition of spent malt rootlets had a positive influence on the sensorial and nutritional composition of biscuits such as minerals, fatty acid content, and highly improved the aroma volatile compounds of the baked goods [60].

It is worthy of note that a combination of fermentation treatment together with an enzymatic one could be the best solution for improving textural characteristics, loaf volume and enhancing the shelf life of the bread enriched with wheat bran [75].

The utilization of brewer spent grain in breadsticks manufacturing was mentioned by Ktenioudaki et al., [63] as displayed in Table 1, and its utilization in bread manufacturing was mentioned by Fărcaș et al., [65] and Baiano et al., [64]. The use of brewer spent grain previously fermented with

On the other side, the utilization of the selected by-products in gastronomy products is displayed in Table 1. The use of wheat bran extract in a percentage of 0.8% in beef meat hamburgers significantly increases the global antioxidant response and the product oxidation stability [68] with possible benefits on human health. It is worth to mention also that wheat bran was used in percentages of 5, 10, 15, and 20% in low-fat meatballs and highly improved the weight loss, the nutritional content of the meatballs (protein, ash), color attributes, decreased the salt content, and registered the lowest moisture. From the sensorial characteristics, the samples with 20% wheat bran addition encoded the biggest firmness, probably because the addition of wheat bran decreased total fat content [69].

It is worth mentioning that these by-products could be successfully used in gastronomy, specifically in the meat manufacturing products. For instance, the utilization of brewer spent grain in the meat products was mentioned by Talens et al., [71] who demonstrated that brewer spent grain could be used as a source of protein in the hybrid sausages, whilst, Kim et al., [72] used brewer spent grain in the chicken patties in a percentage addition of 3%. Corn bran improves the fiber of cooked Turkish meatballs and decreases their fat content [70], meantime, a 3% addition of brewer spent grain does not affect the textural and sensorial characteristics of the smoked sausages [73]. In the beef frankfurters manufacturing, brewer spent grain could be used as a fat substitute for produce products with high dietary fiber and low-fat content [74].

5. Health impact of cereal by-products consumption

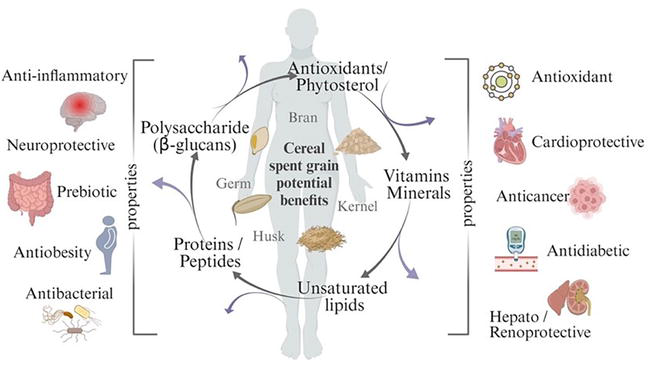

The main positive effects of cereal by-products consumption on human health are presented in Figure 3. The major antioxidants from rice bran are γ-oryzanol, phytosterol from which campesterol, sitosterol, and stigmasterol are the major ones, and tocols (tocotrienol and tocopherol). Tocols, also entitled vitamin E are known to be natural antioxidants with positive effects on certain cancer cells and to reduce the cholesterol concentration, [76] as shown in Table 2. Rice bran is also a rich source of B-complex vitamins, carotenoids, phenolic compounds, octacosanol, and also squalene [82]. It is worthy of note that in rice bran and its products, more than 100 antioxidant compounds were identified from which 12 phenolic acid and several flavonoids such as tricin, quercetin, luteolin, kaempferol, and apigenin [82].

Figure 3.

Main human positive effects of cereal by-products consumption.

| Cereal by-products | Bioactive compound | Beneficial properties |

|---|---|---|

| Rice bran | Bioactive peptides | control of hypertension, oxidative stress, type 2 diabetes mellitus, and various abnormal cellular processes [77]. |

| Wheat germ | Wheat germ extract | fermented wheat germ extracts beneficial effect against ovarian cancer with anti-inflammatory and immunomodulatory effects [78]. |

| Wheat bran | Arabinoxylan oligosaccharides | Improve glucose tolerance, insulin sensitivity mechanism, and gut fermentation improved [79]. |

| Wheat bran | Arabinoxylans and β-glucans | Play a key role in reducing the susceptibility to type II diabetes, colorectal cancer, as well as cardiovascular and diverticular diseases, [29] |

| Wheat bran | Phenolic acid Ferulic acid | ↑ Antioxidant properties, protection against heart diseases and cancer [80]. Cardiovascular diseases, chronic diseases [31]. |

| Corn bran | Arabinoxylans | Prebiotic effect, improve bowel movement, improve the development of colonic microbiota, and the production of exopolysaccharides [5]. Improve gut microbiota modulation [81] |

| Corn bran | Dietary fiber | 52 g/day reduce triglyceride content, glycosylated hemoglobin, and very low-density lipoprotein cholesterol [12]; ↑ fecal bulk, ↓ gastrointestinal transit time, and ↑ colon health [12] |

| Corn bran | Hemicellulose | 10 g/day for 6 months improve obese individual’s glycemic and insulinemic responses [12] |

| Rice bran | γ-oryzanol | Antioxidant activity, lipid-lowering effect, antidiabetic effect, and anti-cancer properties; improve kidney and liver functions in rats [15] |

| Rice bran | γ-oryzanol, tocols, phytosterols | Antioxidant, hypocholesterolemia effects; ↓ serum cholesterol concentration [76] |

| Rice bran | Polysaccharides | Weight reduction, antihypertensive, and hypolipidemic activity [15] |

| Rice bran | Dietary fiber | Prebiotic characteristics [15] |

| Rice bran | Phenolic acid and flavonoids | Antioxidant and antimicrobial effect [82] |

| Rice bran | Arabinoxylan and β-glucan | Functional polysaccharides with immunomodulatory effects on mammary tumors, gastrointestinal cancers, and Lewis lung carcinomas [82] |

| Rice bran | Oryzatensin | Bioactive peptide with immunomodulatory effects [82] |

| Black bran extracts | Cyanidin-3-O-glucoside Peonidin-3-O-glucoside | ↑ antioxidant and anti-inflammatory properties [14] |

| Brewer spent grain | Phenolic compounds | ↑ Antioxidant activity, immunomodulatory effect; antimutagenic effects and DNA-protective [17] |

| Brewer spent grain | β-Glucan | ↑ colon functionality [82] ↓ plasma cholesterol [64] |

| Brewer spent grain | Peptides | Thrombin inhibitory activity [83] |

| Brewer spent grain | Arabinoxylans | ↓ serum cholesterol; ↑ calcium and magnesium adsorption; antioxidant properties [64] |

| Brewer spent grain | Ferulic acid | Antioxidant, anti-inflammatory, and antimicrobial [36] |

| Brewer spent grain | Protein hydrolysate | Antioxidant and antidiabetic effects [61] |

| Spent malt rootlets | Protein hydrolysates | ↑ antihypertensive activity [84] |

Table 2.

Human benefits of cereal by-products bioactive compounds.

↑ increase; ↓ decrease.

Cyanidin-3-O-glucoside and peonidin-3-O-glucoside were the main compounds identified in glutinous black rice varieties with higher anti-inflammatory and antioxidant effects than non-glutinous rice varieties [14]. The oral administration of a formulation comprising powdered black rice and bran among a group of healthy individuals aged between 65 and 75 years resulted in a reduction in the levels of the inflammatory marker IL-6 and C-reactive protein [14].

In a study where hemicellulose was extracted from corn bran, rice bran, and wheat bran, using the same extraction method, and submitted to human fecal microflora for the

The effective fermentation of corn bran hemicellulose, leading to the production of short-chain fatty acids (SCFAs), suggests its potential to contribute to colon health benefits upon consumption [12].

Brewer spent grain β-glucan molar mass is highly influenced by the proteolytic enzymes of the gastrointestinal tract, enhancing its functional role in the colon [83]. Briefly, it seems that proteins could be linked to β-glucan and therefore could affect the molar mass where a key role in the β-glucan hydrodynamic size is played by the enzymatic treatment [85]. Peptides hydrolysates of brewer spent grain are able to inhibit coagulation factors in the blood coagulation pathway and inhibit the thrombin action, thereby preventing the fibrin conversion to fibrinogen [83].

Protein hydrolysates extracts from spent malt rootlets grain treated with different enzymes showed a high angiotensin-converting enzyme (ACE) inhibitory activity and could also have an antihypertensive effect [84].

6. Conclusion

The ever-increasing demand for healthy food correlated with the need of a sustainable future economy, gained researchers’ attention, and increased the utilization of by-products in food manufacturing process. Cereal by-products are rich sources of several bioactive compounds such as dietary fiber, protein, amino acids, minerals, phenolic acids, flavonoids, and vitamins. Unfortunately, there are several antinutrients factors and macromolecular complexes (such as that of protein and fiber) that influence in a negative way the bioaccesibility and biodisponibility of the aforementioned bioactive compounds. Moreover, from the technological point of view, some cereal by-products lead to undesirable texture profiles of the final products such as increased hardness and cohesiveness values and a decrease in gumminess and chewiness attributes.

A way to tackle this drawback is the use of pretreatments such as submerged fermentation or solid-state fermentation of cereal by-products with different lactic acid bacteria strains or even enzymatic treatments. Moreover, extrusion is a new tool that could improve the fiber solubility with no negative effects on other bioactive compounds. The further valorization of these by-products in bakery, pastry, and gastronomy products represents a shift toward a circular food economy system and improves the nutritional value of the final products. This chapter is an important step in the journey toward a new possibility to valorize cereal by-product.

Acknowledgments

This research was supported by a grant of the Romanian Ministry of Education and Research, CCCDI-UEFISCDI, project number PN-III-P2-2.1-PED-2019-3622, within PNCDI III.

References

- 1.

Guo H, Wu H, Sajid A, Li Z. Whole grain cereals: The potential roles of functional components in human health. Critical Reviews in Food Science and Nutrition. 2022; 62 (30):8388-8402. DOI: 10.1080/10408398.2021.1928596 - 2.

Papageorgiou M, Skendi A. In: Galanakis CM, editor. Sustainable Recovery and Reutilization of Cereal Processing by-Products Introduction to Cereal Processing and by-Products. Sawston, United Kingdom: Woodhead Publishing Series in Food Science, Technology and Nutrition, Elsevier; 2018. pp. 1-25. DOI: 10.1016/B978-0-08-102162-0.00001-0 - 3.

Luithui Y, Baghya Nisha R, Meera MS. Cereal by-products as an important functional ingredient: Effect of processing. Journal of Food Science and Technology. 2019; 56 (1):1-11. DOI: 10.1007/s13197-018-3461-y - 4.

Arzami AN, Ho TM, Mikkonen KS. Valorization of cereal by-product hemicelluloses: Fractionation and purity considerations. Food Research International. 2022; 151 :1-21. DOI: 10.1016/j.foodres.2021.110818 - 5.

Fărcaș AC, Socaci SA, Nemeș SA, Pop OL, Coldea TE, Fogarasi M, et al. An update regarding the bioactive compound of cereal by-products: Health benefits and potential applications. Nutrients. 2022; 14 (17):1-19. DOI: 10.3390/nu14173470 - 6.

Salazar-lópez NJ, Ovando-martínez M, Domínguez-avila JA. Cereal/grain by-products. In: Campos-Vega R, Dave Oomah B, Vergara-Castañeda HA, editors. Food Wastes and by-Products: Nutraceutical and Health Potential. John Wiley & Sons Ltd; 2020. pp. 1-34. DOI: 10.1002/9781119534167 - 7.

Fărcaș A, Drețcanu G, Pop TD, Enaru B, Socaci S, Diaconeasa Z. Cereal processing by-products as rich sources of phenolic compounds and their potential bioactivities. Nutrients. 2021; 13 (11):1-17. DOI: 10.3390/nu13113934 - 8.

Alabiden Tlais AZ, Fiorino GM, Polo A, Filannino P, Di Cagno R. High-value compounds in fruit, vegetable and cereal byproducts: An overview of potential sustainable reuse and exploitation. Molecules. 2020; 25 :1-27. DOI: 10.3390/molecules25132987 - 9.

Koistinen VM, Tuomainen M, Lehtinen P, Peltola P, Auriola S, Jonsson K, et al. Side-stream products of malting: A neglected source of phytochemicals. npj Science of Food. 2020; 4 (1):1-9. DOI: 10.1038/s41538-020-00081-0 - 10.

Roth M, Jekle M, Becker T. Opportunities for upcycling cereal byproducts with special focus on Distiller’s grains. Trends in Food Science and Technology. 2019; 91 :282-293. DOI: 10.1016/j.tifs.2019.07.041 - 11.

Skendi A, Zinoviadou KG, Papageorgiou M, Rocha JM. Advances on the valorisation and functionalization of by-products and wastes from cereal-based processing industry. Food. 2020; 9 :1-28. DOI: 10.3390/foods9091243 - 12.

Ai Y, Jane JL. Macronutrients in corn and human nutrition. Comprehensive Reviews in Food Science and Food Safety. 2016; 15 (3):581-598. DOI: 10.1111/1541-4337.12192 - 13.

Singh M, Liu SX, Vaughn SF. Effect of corn bran as dietary fiber addition on baking and sensory quality. Biocatalysis and Agricultural Biotechnology. 2012; 1 (4):348-352. DOI: 10.1016/j.bcab.2012.02.005 - 14.

Mapoung S, Semmarath W, Arjsri P, Thippraphan P, Srisawad K, Umsumarng S, et al. Comparative analysis of bioactive-phytochemical characteristics, antioxidants activities, and anti-inflammatory properties of selected black rice germ and bran ( Oryza sativa L.) varieties. European Food Research and Technology. 2023;249 (2):451-464. DOI: 10.1007/s00217-022-04129-1 - 15.

Sapwarobol S, Saphyakhajorn W, Astina J. Biological functions and activities of Rice bran as a functional ingredient: A review. Nutrition and Metabolic Insights. 2021; 14 :1-11. DOI: 10.1177/11786388211058559 - 16.

Aggelopoulos T, Bekatorou A, Pandey A, Kanellaki M, Koutinas AA. Discarded oranges and brewer’s spent grains as promoting ingredients for microbial growth by submerged and solid state fermentation of agro-industrial waste mixtures. Applied Biochemistry and Biotechnology. 2013; 170 (8):1885-1895. DOI: 10.1007/s12010-013-0313-0 - 17.

Naibaho J, Korzeniowska M. Brewers’ spent grain in food systems: Processing and final products quality as a function of fiber modification treatment. Journal of Food Science. 2021; 86 (5):1532-1551. DOI: 10.1111/1750-3841.15714 - 18.

Olivares-Galván S, Marina ML, García MC. Extraction of valuable compounds from brewing residues: Malt rootlets, spent hops, and spent yeast. Trends in Food Science and Technology. 2022; 127 :181-197. DOI: 10.1016/j.tifs.2022.06.002 - 19.

Fărcaș AC, Socaci SA, Chiș MS, Martí J. In vitro digestibility of minerals and B vitamins group from different brewers’ spent grains. Nutrients. 2022; 27 (7):1-15. DOI: 10.3390/plants10112504 - 20.

Ludka FR, Klosowski AB, Camargo GA, Justo AS, Andrade EA, Beltrame FL, et al. Brewers’ spent grain extract as antioxidants in starch-based active biopolymers. International Journal of Food Science and Technology. 2024; 59 (1):142-150. DOI: 10.1111/ijfs.16785 - 21.

Neylon E, Nyhan L, Zannini E, Sahin AW, Arendt EK. From waste to taste: Application of fermented spent rootlet ingredients in a bread system. Food. 2023; 12 (7):1-25. DOI: 10.3390/foods12071549 - 22.

Neylon E, Arendt EK, Lynch KM, Zannini E, Bazzoli P, Monin T, et al. Rootlets, a malting by-product with great potential. Fermentation. 2020; 6 (4):117. DOI: 10.3390/fermentation6040117 - 23.

Budaraju S, Mallikarjunan K, Annor G, Schoenfuss T, Raun R. Effect of pre-treatments on the antioxidant potential of phenolic extracts from barley malt rootlets. Food Chemistry. 2018; 266 :31-37. DOI: 10.1016/j.foodchem.2018.05.110 - 24.

Karlović A, Jurić A, Ćorić N, Habschied K, Krstanović V, Mastanjević K. By-products in the malting and brewing industries-re-usage possibilities. Fermentation. 2020; 6 (3):1-17. DOI: 10.3390/FERMENTATION6030082 - 25.

Pejin J, Radosavljević M, Pribić M, Kocić-Tanackov S, Mladenović D, Djukić-Vuković A, et al. Possibility of L-(+)-lactic acid fermentation using malting, brewing, and oil production by-products. Waste Management. 2018; 79 :153-163. DOI: 10.1016/j.wasman.2018.07.035 - 26.

Parenti O, Guerrini L, Zanoni B. Techniques and technologies for the breadmaking process with unrefined wheat flours. Trends in Food Science and Technology. 2020; 99 :152-166. DOI: 10.1016/j.tifs.2020.02.034 - 27.

Navrotskyi S, Guo G, Baenziger PS, Xu L, Rose DJ. Impact of wheat bran physical properties and chemical composition on whole grain flour mixing and baking properties. Journal of Cereal Science. 2019; 89 :102790. DOI: 10.1016/j.jcs.2019.102790 - 28.

Acin-Albiac M, Filannino P, Arora K, Da Ros A, Gobbetti M, Di Cagno R. Role of lactic acid bacteria phospho-β-glucosidases during the fermentation of cereal by-products. Food. 2021; 10 (1):1-14. DOI: 10.3390/foods10010097 - 29.

Verni M, Rizzello CG, Coda R. Fermentation biotechnology applied to cereal industry by-products: Nutritional and functional insights. Frontiers in Nutrition. 2019; 6 :1-13. DOI: 10.3389/fnut.2019.00042 - 30.

Spaggiari M, Ricci A, Calani L, Bresciani L, Neviani E, Dall’Asta C, et al. Solid state lactic acid fermentation: A strategy to improve wheat bran functionality. LWT. 2020; 118 :108668. DOI: 10.1016/j.lwt.2019.108668 - 31.

Deroover L, Tie Y, Verspreet J, Courtin CM, Verbeke K. Modifying wheat bran to improve its health benefits. Critical Reviews in Food Science and Nutrition. 2020; 60 (7):1104-1122. DOI: 10.1080/10408398.2018.1558394 - 32.

Rezaei S, Najafi MA, Haddadi T. Effect of fermentation process, wheat bran size and replacement level on some characteristics of wheat bran, dough, and high-fiber Tafton bread. Journal of Cereal Science. 2019; 85 :56-61. DOI: 10.1016/j.jcs.2018.11.019 - 33.

Hartikainen K, Poutanen K, Katina K. Influence of bioprocessed wheat bran on the physical and chemical properties of dough and on wheat bread texture. Cereal Chemistry. 2014; 91 (2):115-123. DOI: 10.1094/CCHEM-04-13-0074-R - 34.

Bolarinwa IF, Hanis-Syazwani MG, Muhammad K. Optimisation of important processing conditions for rice bran sourdough fermentation using L actobacillus plantarum . Foods and Raw Materials. 2019;7 (1):131-142. DOI: 10.21603/2308-4057-2019-1-131-142 - 35.

Neylon E, Nyhan L, Zannini E, Monin T, Münch S, Sahin AW, et al. Food ingredients for the future: In-depth analysis of the effects of lactic acid Bacteria fermentation on spent barley rootlets. Fermentation. 2023; 9 (1):1-21. DOI: 10.3390/fermentation9010078 - 36.

L-Shwafy KWA, Chadni M, Hariz Abg Zamari MH, Ioannou I. Enzymatic extraction of ferulic acid from brewer’s spent grain: Effect of physical pretreatments and optimization using design of experiments. Biocatalysis and Agricultural Biotechnology. 2023; 51 :1-11. DOI: 10.1016/j.bcab.2023.102779 - 37.

Bazsefidpar N, Ahmadi Gavlighi H, Ghandehari Yazdi AP, Jafari SM. Optimization of protein extraction from brewer’s spent grain and production of bioactive peptides. Biomass Convers Biorefinery. 2023:1-11. DOI: 10.1007/s13399-023-03932-4 - 38.

Roasa J, De Villa R, Mine Y, Tsao R. Phenolics of cereal, pulse and oilseed processing by-products and potential effects of solid-state fermentation on their bioaccessibility, bioavailability and health benefits: A review. Trends in Food Science and Technology. 2021; 116 :954-974. DOI: 10.1016/j.tifs.2021.08.027 - 39.

Cervantes-Ramirez JG, Vasquez-Lara F, Sanchez-Estrada A, Troncoso-Rojas R, Heredia-Olea E, Islas-Rubio AR. Arabinoxylans release from brewers’ spent grain using extrusion and solid-state fermentation with fusarium oxysporum and the antioxidant capacity of the extracts. Food. 2022;11 (10):1-15. DOI: 10.3390/foods11101415 - 40.

Cooray ST, Chen WN. Valorization of brewer’s spent grain using fungi solid-state fermentation to enhance nutritional value. Journal of Functional Foods. 2018; 42 :85-94. DOI: 10.1016/j.jff.2017.12.027 - 41.

Bianco A, Zara G, Garau M, Castaldi P, Atzori AS, Deroma MA, et al. Microbial community assembly and chemical dynamics of raw brewers’ spent grain during inoculated and spontaneous solid-state fermentation. Waste Management. 2024; 174 :518-527. DOI: 10.1016/j.wasman.2023.12.021 - 42.

Chen Y, Ma Y, Dong L, Jia X, Liu L, Huang F, et al. Extrusion and fungal fermentation change the profile and antioxidant activity of free and bound phenolics in rice bran together with the phenolic bioaccessibility. LWT. 2019; 115 :108461. DOI: 10.1016/j.lwt.2019.108461 - 43.

Adebo JA, Njobeh PB, Gbashi S, Oyedeji AB, Ogundele OM, Oyeyinka SA, et al. Fermentation of cereals and legumes: Impact on nutritional constituents and nutrient bioavailability. Fermentation. 2022; 8 (2):1-57. DOI: 10.3390/fermentation8020063 - 44.

Orozco-Angelino X, Espinosa-Ramírez J, Serna-Saldívar SO. Extrusion as a tool to enhance the nutritional and bioactive potential of cereal and legume by-products. Food Research International. 2023; 169 :1-13. DOI: 10.1016/j.foodres.2023.112889 - 45.

Sun X, Dou Z, Shurson GC, Hu B. Bioprocessing to upcycle agro-industrial and food wastes into high-nutritional value animal feed for sustainable food and agriculture systems. Resources, Conservation and Recycling. 2024; 201 :1-13. DOI: 10.1016/j.resconrec.2023.107325 - 46.

Igual M, García-Segovia P, Martínez-Monzó J. Effect of Acheta domesticus (house cricket) addition on protein content, colour, texture, and extrusion parameters of extruded products. Journal of Food Engineering. 2020;282 :1-7. DOI: 10.1016/j.jfoodeng.2020.110032 - 47.

Grasso S. Extruded snacks from industrial by-products: A review. Trends in Food Science and Technology. 2020; 99 :284-294. DOI: 10.1016/j.tifs.2020.03.012 - 48.

Aktas-Akyildiz E, Masatcioglu MT, Köksel H. Effect of extrusion treatment on enzymatic hydrolysis of wheat bran. Journal of Cereal Science. 2020; 93 (8):1-7. DOI: 10.1016/j.jcs.2020.102941 - 49.

Haghighi-Manesh S, Azizi MH. Integrated extrusion-enzymatic treatment of corn bran for production of functional cake. Food Science & Nutrition. 2018; 6 (7):1870-1878. DOI: 10.1002/fsn3.738 - 50.

Santos D, Pintado M, Lopes da Silva JA. Potential nutritional and functional improvement of extruded breakfast cereals based on incorporation of fruit and vegetable by-products – A review. Trends in Food Science and Technology. 2022; 125 :136-153. DOI: 10.1016/j.tifs.2022.05.010 - 51.

Rafe A, Sadeghian A, Hoseini-Yazdi SZ. Physicochemical, functional, and nutritional characteristics of stabilized rice bran form tarom cultivar. Food Science & Nutrition. 2017; 5 (3):407-414. DOI: 10.1002/fsn3.407 - 52.

Wang P, Fu Y, Wang L, Saleh ASM, Cao H, Xiao Z. Effect of enrichment with stabilized rice bran and extrusion process on gelatinization and retrogradation properties of rice starch. Starch/Staerke. 2017; 69 (7-8). DOI: 10.1002/star.201600201 - 53.

Sousa MF d, Guimarães RM, Araújo M d O, Barcelos KR, Carneiro NS, Lima DS, et al. Characterization of corn ( Zea mays L.) bran as a new food ingredient for snack bars. LWT. 2019;101 :812-888. DOI: 10.1016/j.lwt.2018.11.088 - 54.

Sharma S, Gupta JP, Nagi HPS, Kumar R. Effect of incorporation of corn byproducts on quality of baked and extruded products from wheat flour and semolina. Journal of Food Science and Technology. 2012; 49 (5):580-600. DOI: 10.1007/s13197-011-0304-5 - 55.

Messia MC, Reale A, Maiuro L, Candigliota T, Sorrentino E, Marconi E. Effects of pre-fermented wheat bran on dough and bread characteristics. Journal of Cereal Science. 2016; 69 :138-144. DOI: 10.1016/j.jcs.2016.03.004 - 56.

Li Z, Wang Z, Li LM, Zheng XL, Ma S. Effects of fermented wheat bran on flour, dough, and steamed bread characteristics. Journal of Chemistry. 2018; 51 :1-7. DOI: 10.1155/2018/1597308 - 57.

Christ-Ribeiro A, Chiattoni LM, Mafaldo CRF, Badiale-Furlong E, Souza-Soares LA d. Fermented rice-bran by Saccharomyces cerevisiae : Nutritious ingredient in the formulation of gluten-free cookies. Food Bioscience. 2021;40 :100859. DOI: 10.1016/j.fbio.2020.100859 - 58.

Sairam S, Gopala Krishna AG, Urooj A. Physico-chemical characteristics of defatted rice bran and its utilization in a bakery product. Journal of Food Science and Technology. 2011; 48 (4):478-483. DOI: 10.1007/s13197-011-0262-y - 59.

Neylon E, Arendt EK, Zannini E, Sahin AW. Fermentation as a tool to revitalise brewers’ spent grain and elevate techno-functional properties and nutritional value in high fibre bread. Food. 2021; 10 (7):1-20. DOI: 10.3390/foods10071639 - 60.

Chiş MS, Pop A, Păucean A, Socaci SA, Alexa E, Man SM, et al. Fatty acids, volatile and sensory profile of multigrain biscuits enriched with spent malt rootles. Molecules. 2020; 25 (3):1-17. DOI: 10.3390/molecules25030442 - 61.

Bazsefidpar N, Ghandehari Yazdi AP, Karimi A, Yahyavi M, Amini M, Ahmadi Gavlighi H, et al. Brewers spent grain protein hydrolysate as a functional ingredient for muffins: Antioxidant, antidiabetic, and sensory evaluation. Food Chemistry. 2024; 435 :1-6. DOI: 10.1016/j.foodchem.2023.137565 - 62.

Waters DM, Jacob F, Titze J, Arendt EK, Zannini E. Fibre, protein and mineral fortification of wheat bread through milled and fermented brewer’s spent grain enrichment. European Food Research and Technology. 2012; 235 (5):767-778. DOI: 10.1007/s00217-012-1805-9 - 63.

Ktenioudaki A, Chaurin V, Reis SF, Gallagher E. Brewer’s spent grain as a functional ingredient for breadsticks. International Journal of Food Science and Technology. 2012; 47 (8):1765-1771. DOI: 10.1111/j.1365-2621.2012.03032.x - 64.

Baiano A, la Gatta B, Rutigliano M, Fiore A. Functional bread produced in a circular economy perspective: The use of brewers’ spent grain. Food. 2023; 12 (4):1-27. DOI: 10.3390/foods12040834 - 65.

Fărcaş AC, Socaci SA, Tofană M, Mureşan C, Mudura E, Salanţă L, et al. Nutritional properties and volatile profile of brewer’s spent grain supplemented bread. Romanian Biotechnology Letters. 2014; 19 (5):9705-9714 - 66.

Nocente F, Taddei F, Galassi E, Gazza L. Upcycling of brewers’ spent grain by production of dry pasta with higher nutritional potential. LWT. 2019; 114 :1-6. DOI: 10.1016/j.lwt.2019.108421 - 67.

Kumar P, Chatli MK, Mehta N, Malav OP, Verma AK, Kumar D. Quality attributes and storage stability of chicken meat biscuits incorporated with wheat and oat bran. Journal of Food Quality. 2016; 39 (6):649-657. DOI: 10.1111/jfq.12232 - 68.

Šulniute V, Jaime I, Rovira J, Venskutonis PR. Rye and wheat bran extracts isolated with pressurized solvents increase oxidative stability and antioxidant potential of beef meat hamburgers. Journal of Food Science. 2016; 81 (2):H519-H527. DOI: 10.1111/1750-3841.13197 - 69.

Yilmaz I. Physicochemical and sensory characteristics of low fat meatballs with added wheat bran. Journal of Food Engineering. 2005; 69 (3):369-373. DOI: 10.1016/j.jfoodeng.2004.08.028 - 70.

Yasarlar EE, Daglioglu O, Yilmaz I. Effects of cereal bran addition on chemical composition, cooking characteristics and sensory properties of Turkish meatballs. Asian Journal of Chemistry. 2007; 19 (3):2353-2361 - 71.

Talens C, Llorente R, Simó-Boyle L, Odriozola-Serrano I, Tueros I, Ibargüen M. Hybrid sausages: Modelling the effect of partial meat replacement with broccoli, upcycled Brewer’s spent grain and insect flours. Food. 2022; 11 (21):1-18. DOI: 10.3390/foods11213396 - 72.

Kim HW, Hwang KE, Song DH, Lee SY, Choi MS, Bin LY, et al. Effects of dietary fiber extracts from brewer’s spent grain on quality characteristics of chicken patties cooked in convective oven. Korean Journal for Food Science of Animal Resources. 2013; 33 (1):45-52. DOI: 10.5851/kosfa.2013.33.1.45 - 73.

Nagy M, Semeniuc CA, Socaci SA, Pop CR, Rotar AM, Sălăgean CD, et al. Utilization of brewer’s spent grain and mushrooms in fortification of smoked sausages. Food Science and Technology. 2017; 37 (2):315-320. DOI: 10.1590/1678-457X.23816 - 74.

Özvural EB, Vural H, Gökbulut I, Özboy-Özbaş Ö. Utilization of brewer’s spent grain in the production of frankfurters. International Journal of Food Science and Technology. 2009; 44 (6):1093-1099. DOI: 10.1111/j.1365-2621.2009.01921.x - 75.

Hemdane S, Jacobs PJ, Dornez E, Verspreet J, Delcour JA, Courtin CM. Wheat ( Triticum aestivum L.) bran in bread making: A critical review. Comprehensive Reviews in Food Science and Food Safety. 2016;15 (1):28-42. DOI: 10.1111/1541-4337.12176 - 76.

Raghav PK, Agarwal N, Sharma A. Emerging health benefits of rice bran – A review. IJMRME. 2016; 2 (1):367-382 - 77.

Udenigwe CC. Towards rice bran protein utilization: In silico insight on the role of oryzacystatins in biologically-active peptide production. Food Chemistry. 2016; 191 :135-138. DOI: 10.1016/j.foodchem.2015.01.043 - 78.

Koh EM, Lee EK, Song J, Kim SJ, Song CH, Seo Y, et al. Anticancer activity and mechanism of action of fermented wheat germ extract against ovarian cancer. Journal of Food Biochemistry. 2018; 42 (6):1-11. DOI: 10.1111/jfbc.12688 - 79.

Boll EVJ, Ekström LMNK, Courtin CM, Delcour JA, Nilsson AC, Björck IME, et al. Effects of wheat bran extract rich in arabinoxylan oligosaccharides and resistant starch on overnight glucose tolerance and markers of gut fermentation in healthy young adults. European Journal of Nutrition. 2016; 55 (4):1661-1670. DOI: 10.1007/s00394-015-0985-z - 80.

Saini A, Panwar D, Panesar PS. Bioactive compounds from cereal and pulse processing. Austin Journal of Nutrition & Metabolism. 2019; 6 (2):1-7 - 81.

Nguyen NK, Deehan EC, Zhang Z, Jin M, Baskota N, Perez-Muñoz ME, et al. Gut microbiota modulation with long-chain corn bran arabinoxylan in adults with overweight and obesity is linked to an individualized temporal increase in fecal propionate. Microbiome. 2020; 8 (1):1-21. DOI: 10.1186/s40168-020-00887-w - 82.

Park HY, Lee KW, Choi HD. Rice bran constituents: Immunomodulatory and therapeutic activities. Food & Function. 2017; 8 (3):935-943. DOI: 10.1039/c6fo01763k - 83.

Cian RE, Garzón AG, Martínez-Augustin O, Botto CC, Drago SR. Antithrombotic activity of brewers’ spent grain peptides and their effects on blood coagulation pathways. Plant Foods for Human Nutrition. 2018; 73 (3):241-246. DOI: 10.1007/s11130-018-0682-1 - 84.

Sentís-Moré P, Ortega-Olivé N, Egea-Vilches C, Romero-Fabregat MP. Screening of protein hydrolysates from malt rootlets and their relationship with technological properties. LWT. 2023; 182 :1-9. DOI: 10.1016/j.lwt.2023.114864 - 85.

Zielke C, Teixeira C, Ding H, Cui S, Nyman M, Nilsson L. Analysis of β-glucan molar mass from barley malt and brewer’s spent grain with asymmetric flow field-flow fractionation (AF4) and their association to proteins. Carbohydrate Polymers. 2017; 157 :541-549. DOI: 10.1016/j.carbpol.2016.10.045