The correlation coefficients between some geometric, gravimetric, and color properties of floury maize a1 toasted by microwaves.

Abstract

The applications of microwaves for household use and processing at the industrial level have gained immense importance over traditional conduction or convection heating systems. Microwaves can heat and toast raw kernels such as peanuts, maize, hazelnuts, sunflower seeds, cocoa beans, coffee, and other food kernels with a notable decrease in energy consumption and heating time because this technology generates volumetric heating in each kernel with the absorption of the incident energy. However, for raw kernels packaged for toasting, the availability of a continuous or at least intermittent movement device is highly required in microwave ovens. This chapter will briefly discuss the basic principles available in microwave ovens based on the dielectric heating modes. Recent advances and challenges in uniform heating using movement or rotating devices. Also, the pros and cons of applying microwave energy in toasting processing operations will be discussed.

Keywords

- microwave toasting

- dry heating

- microwave-packed kernels

- household microwave ovens

- first-generation snack

1. Introduction

Toasting is a unit operation that involves art and science, and this knowledge has grown from artisanal production to industrial processing of cereals and other dry kernels, with high levels of quality, efficiency, and hygiene. In toasting, sugars react with other carbohydrates and proteins to develop color and flavor compounds [1]. Thus, the toasting process of raw kernels is key to controlling the degree of modification of macro components and the development of aroma, texture, and color profiles of products, converted into edible forms. Specialty raw maize types subjected to traditional and microwave toasting are ready-to-eat kernels with soft and crunchy endosperm [2]. Raw almonds treated in a convective oven [3] and hot air-assisted radio frequency [4] present color, texture, and sensory attributes that meet consumer demands. Toasted peanuts, characterized by sensory analysis and aroma profiles, are critical data for the commercial peanut industry in selecting available cultivars to produce acceptable consumer whole-kernel snacks [5]. Cashew nut kernels toasted by hot air-assisted radio frequency enhance the nutritional quality and flavor [6]. In sunflower kernels, microwave toasting does not reduce the sensory quality of the product as it is expressed by overall consumer preference compared to convection toasting which increases kernels’ hardness [7]. In chickpea snack production, toasting is a common process to improve their texture profile and palatability, so this topic has studies to compare the effect of different toasting methods [8]. On the other hand, toasting is a unit operation to achieve the characteristic flavor and texture in breakfast cereal and snack foods [9, 10]. In the processing of cocoa [11, 12, 13] and coffee [14, 15, 16], toasting develops the required profiles in color, aroma, and flavor sensations. In cereals and pseudocereals, toasting whole kernels could cause structural changes in starch and protein, breaking chains into partially soluble intermediate molecules with technological quality for the development of a variety of functional foods [17, 18, 19]. In legume flour, toasted chickpea kernels can be used in the development of various functional foods [20]. In addition, it has been found that toasting promotes the inhibition of anti-nutritional factors; e.g., phytic acid has decreased by 18% in quinoa toasted at around 180°C for 5 minutes [21]. Toasting is a traditional household process to convert raw seeds into edible kernels. The state of the art suggests that it is a current topic and has aroused great interest in researchers looking for innovation and new ingredients. Toasting is a unitary operation applied on a small, medium, and large scale through conventional and emerging heating systems based on conduction, convection, and radiation principles.

Referring to electromagnetic radiation, microwaves can toast dry raw materials under low temperatures (120–140°C) and short time compared with those of at least 150°C from an open flame, traditional toasting machines by long time and novel electric toasters [22]. Therefore, microwave-toasting household ovens and industrial systems can produce edible and healthy whole kernels in a short time. Hence, microwave ovens can be more efficient than conventional ovens and hot-air toasting technologies. However, most current applications are related to household microwaves with digital touchscreen control that only includes the heating program for popcorn, which does not require intensive movement of the packed kernel. In addition, the available studies aim at industrial toasting applications, where a microwave toasting machine has a feeding system that evenly distributes on the conveyor belt for raw materials like barley, oatmeal, whole kernels, seeds, pistachio, almonds, peanuts, and other nuts.

This chapter overviews recent research and innovation in microwave toasting for household and industrial applications. Also, the need for innovation in household microwave ovens to toast packaged kernels and obtain homemade snacks is addressed. Practical application approaches microwave toasting, and proposed packaging based on those available for microwave popcorn are also discussed. This chapter provides the first look at raw kernels packaged for toasting as a current challenge for microwave technology.

2. Overview on roasting and toasting foods

Dry heat is the heating medium for roasting and toasting methods in food production. Therefore, roasting and toasting raw food matrices do not use water or oil to convert them into ready-to-eat forms with special sensory attributes. Roasting is a culinary art applied to raw foods such as meat, fish, potatoes, plantains, apples, and other vegetables, that is, to raw food matrices with high moisture content (greater than 70%). Toasting, also of ancestral use, is applied to raw food matrices with low moisture content (less than 15%), such as cereals, other kernels, seeds, and dry nuts. Consequently, this chapter discusses the toasting of kernels in household microwave ovens and the findings available to advance microwave applications in the food industry. Figure 1a and b, respectively, illustrate the increasing activity in toasting processes expressed as the total number of publications available worldwide and the average number of publications for three-year periods collected from 2004 to 2024. Studies on popcorn or food materials with intermediate and high moisture content are excluded. Furthermore, interest in microwave toasting is also growing in the cycle evaluated, even though the number of publications and its increase is limited (Figure 2a and b). The general review of the results shows great progress in the last 6 years. It represents a challenge to the current popularity of microwave technology over conventional processes in other fields.

Figure 1.

Number and average of toasting research publications from 2004 to 2024: (a) the total number of publications available worldwide, and (b) an average of publications for three-year periods. Studies on popcorn and other food matrixes with intermediate and high moisture content are excluded.

Figure 2.

Number and average of microwave toasting research publications from 2004 to 2024: (a) the total number of publications available worldwide, and (b) an average of publications for three-year periods. Studies on popcorn and other food matrixes with intermediate and high moisture content are excluded.

3. Raw kernels packaged for microwave toasting

3.1 Current research

Microwave toasting is a topic that has greatly interested researchers and toasting equipment developers worldwide. The knowledge generated shows the potential application of microwave toasting in the different fields of kernels, seed, and nut processing [22]. Recent studies reveal the feasibility of using a household microwave oven to toast maize kernels packed in kraft paper bags by 312–390 seconds. These results suggest that Andean maize types (

3.2 Raw microwave toasting maize types

Specialty maize types for toasting at home are floury maize (

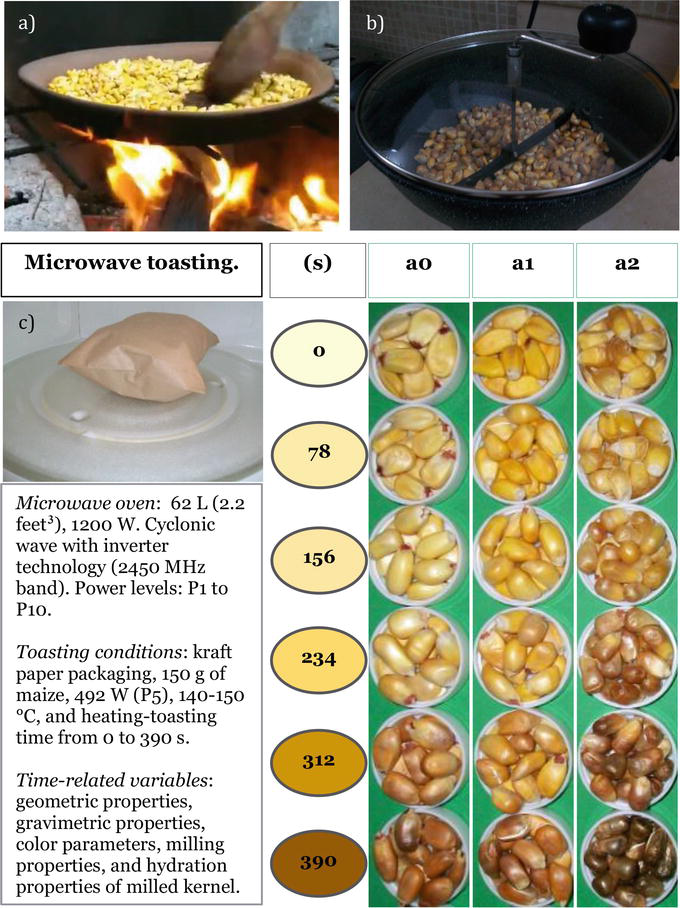

Figure 3.

Approach to maize kernel toasting from ancient to innovative: (a) ancestral toasting method (

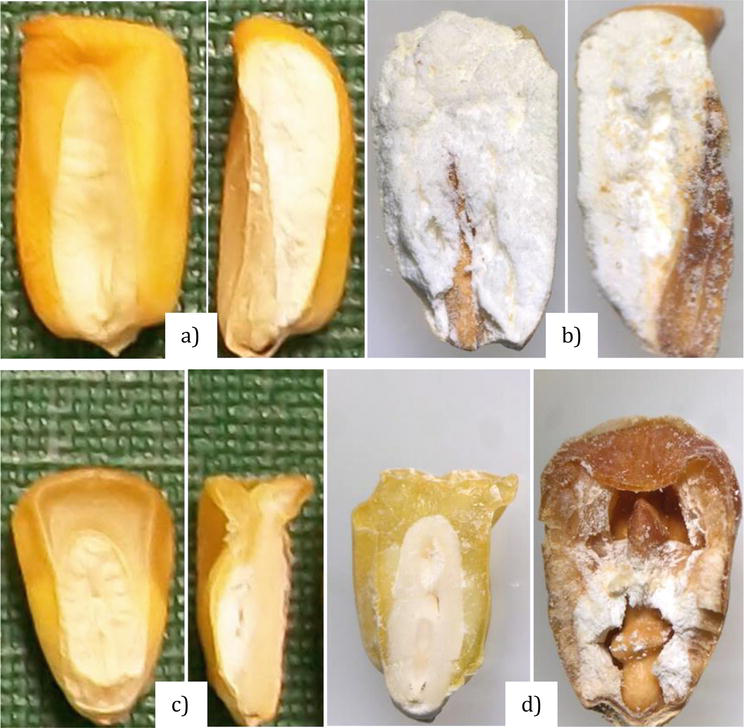

Floury maize used for toasting has kernels with completely soft endosperm, without vitreous fraction. The kernels are elongated in shape and large. The surface color varies from pale yellow to matte yellow, and the endosperm color is white. The toasted kernels are easy to chew, and the surface color changes to golden-brown with significant variations in physical, chemical, structural, and texture properties between raw and toasted kernels [2, 25]. Figure 4a, illustrates that elongated kernels, yellow pericarp, white, and entirely soft endosperm are the main characteristics of floury maize to make “Tostado.” Figure 4b, shows the cross-section of maize kernel after toasting (ready-to-eat maize) with a soft appearance and easy to chew. The completely floury endosperm appears as a simple starch-based material compared to starch-protein and lipid composites from other starchy sources. Therefore, Figure 4(a and b) suggests that these toasted whole kernels can be the first insight into future challenges to modify starch at the whole kernel endosperm level using microwave heating-toasting.

Figure 4.

Specialty maize kernels for toasting before and after being subjected to microwave heating at 492 W for 390 seconds, interspersing rapid manual movement of the packed kernel: (a) raw floury maize, (b) toasted floury maize, (c) raw native sweet maize, (d) toasted native sweet maize. Unpublished photographs.

The mature native sweet maize kernels are shrunken and vitreous after drying. The vitreous fraction is translucent, and the color can vary between beige and yellow. The shrunken endosperm has a sugary-vitreous fraction more significant than the floury endosperm, with high total sugars and water-soluble index [24, 25]. The high water-soluble solids non-converted in starch contribute to the developing crispy texture and more intense golden-brown color in sweet maize than floury maize during toasting [2]. Figure 4c, exhibits a shrunken yellow kernel and cross-section with a sugary-vitreous fraction greater than floury endosperm. Figure 4d, shows the cross-section of maize kernel after toasting (ready-to-eat maize) with a crispy texture to chew. There are significant structural changes between raw (Figure 4c) and toasted sweet kernels (Figure 4d), indicating that sweet maize toasted by microwave can be an interesting first-generation snack food.

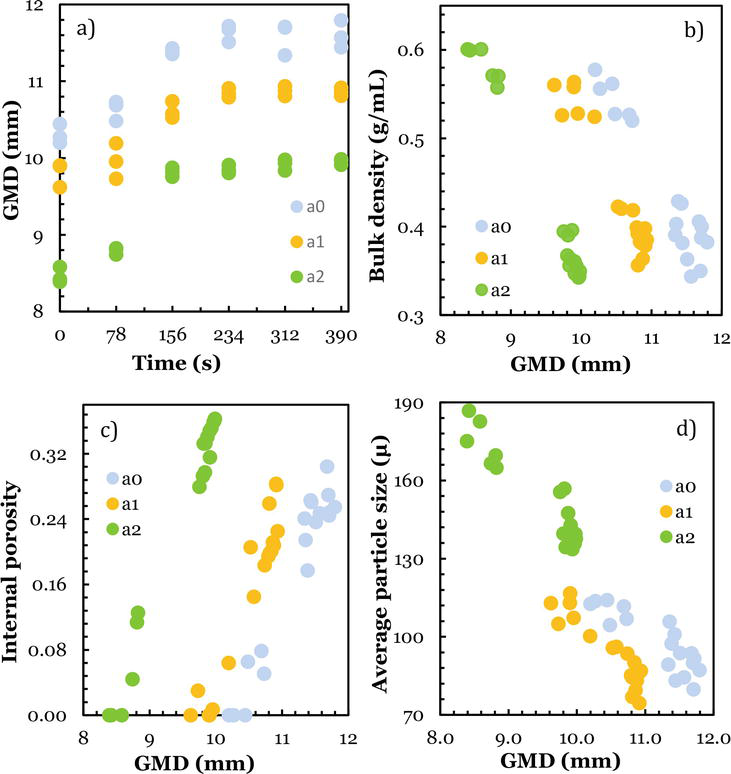

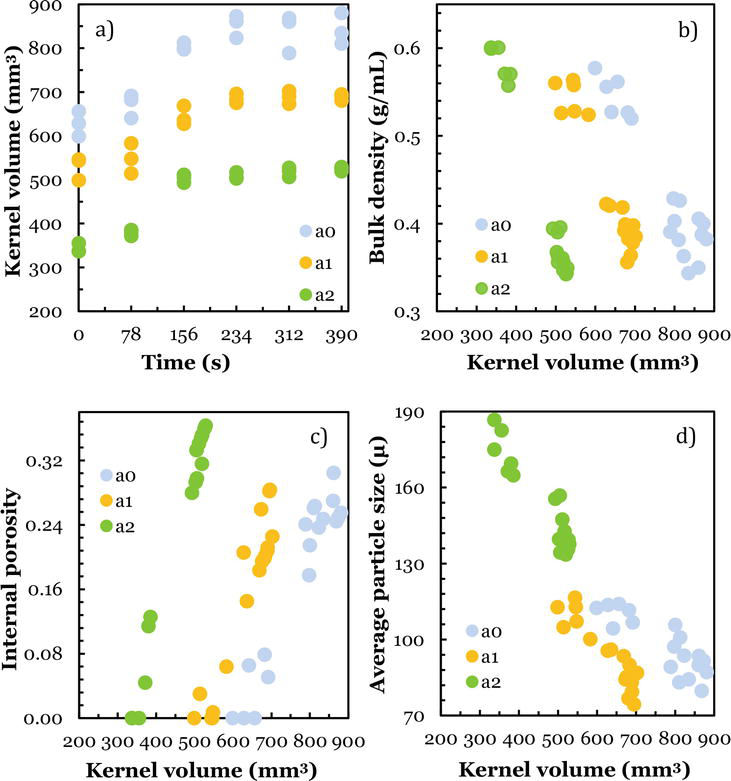

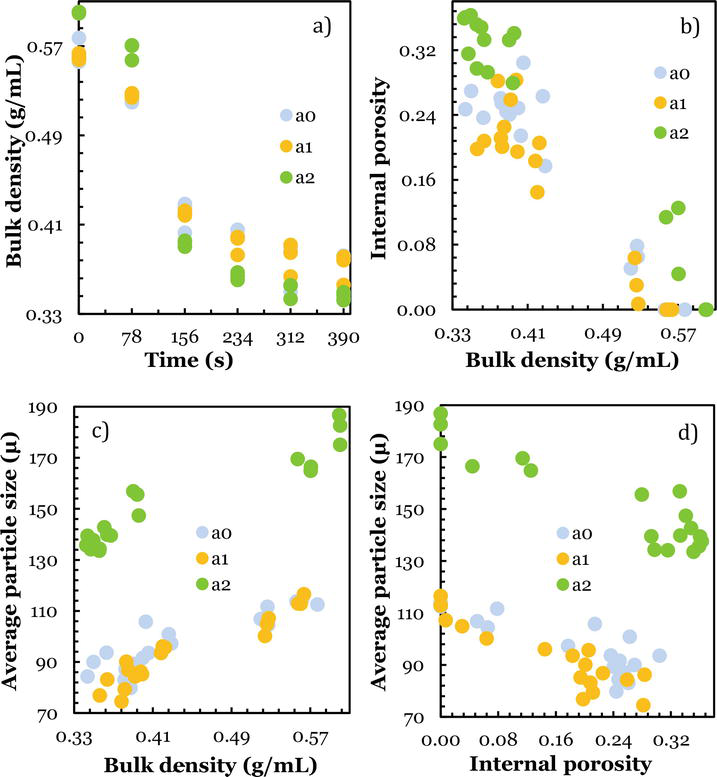

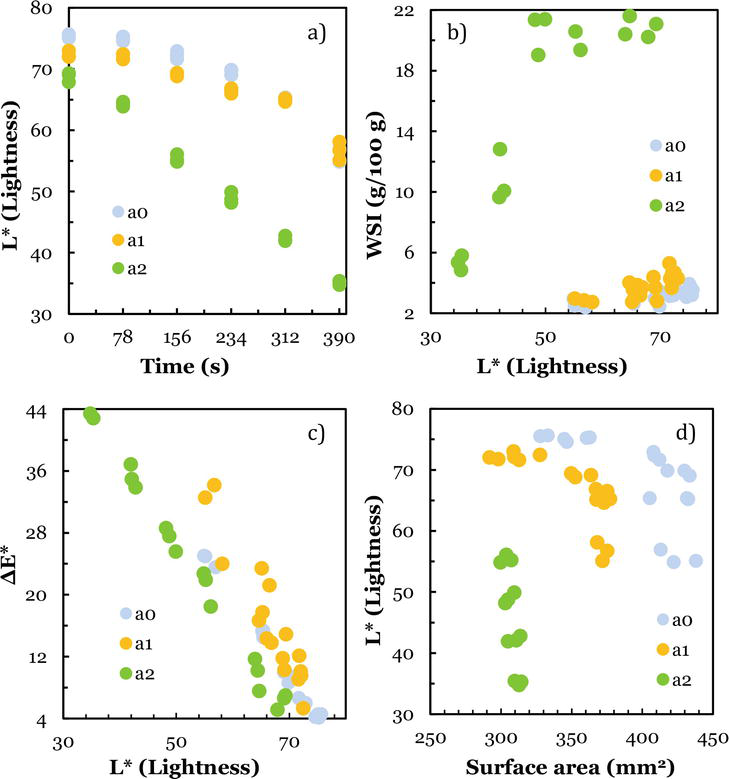

According to the results of microwave heating-toasting at different times, most of the geometric, gravimetric, milling and color properties in maize kernels are time-related variables and correlate between them, reflecting the gradual effect of volumetric heating occurring in individual kernels, e.g., the decrease in density correlates with the increase in the volume of individual kernels due to water loss and kernel expansion with the formation of cavities in the endosperm [23]. Tables 1 and 2 display the correlation coefficients established between the dependent variables used to characterize the microwave toasting of packaged maize kernels. Except for the water-soluble index (WSI) in floury maize, the remaining maize kernel properties are time-related variables. Their correlation coefficients indicate that the raw maize kernels packaged and subjected to microwave treatments mainly depend on geometrical properties because these dependent variables present a high correlation with gravimetric, milling, and color properties, for sweet maize with a smaller kernel size than that for floury maize. Figure 5a reveals that maize kernels’ geometric mean diameter (GMD) is a time-related variable. Based on the characteristic size of each specialty maize for toasting, the GMD separates the microwave heating-toasting effect by type of maize. By plotting against the GMD, the bulk density (Figure 5b), the internal porosity of the whole kernels (Figure 5c), and the average particle size of milled kernels (Figure 5d) display the degree of existing correlation and reflect the influence on each material due to microwave treatment times. Regarding Figure 6a, the volume of maize individual kernels varies by the effect of the microwave treatment time in agreement with the GMD. Thus, the kernel volume correlates with the bulk density, the internal porosity in whole kernels, and the average particle size of milled kernels, as shown in Figure 6(b, c, and d, respectively), demonstrating that maize geometry (size and shape) greatly influences the microwave heating of packaged kernels. Figure 7a shows that the bulk density is a variable related to the microwave treatment time. Figure 7(b–d) show the correlations with the variables associated with the structural properties of the endosperm in floury maize and sweet maize, expressed as internal porosity of whole kernels and average particle size in milled kernels. However, the variation does not contribute to differentiate between maize genotypes with floury endosperm, suggesting that the effect of microwave toasting may be similar for food matrices with the same structural pattern. Figure 8a exhibits the decreasing variation of the space color parameter L* (lightness) by the effect of microwave heating time on the surface color of maize kernels. L* parameter is a time-relate variable whose variation depends on the size of maize kernels. The correlation between the water-soluble index (WSI) and the L* parameter shows the structural difference between sweet and floury maize (Figure 8b). However, the trends between the two types of floury maize are not well separated. A good correlation exists between the increasing overall difference in surface color (ΔE*) and the decreasing L* parameter (Figure 8c). This correlation suggests that rapid measurement of the L* parameter can be considered for quality control of microwave toasting at the industrial level. The parameter L*, relative to the surface ΔE* due to the microwave treatment, correlates with the surface area of the maize kernel and exhibits a clear distinction in the trends of the three materials presented (Figure 8d). This is attributable to the differences in the size and shape of maize kernels, proving that the geometry of the product subjected to microwave treatment influences the color development of the maize surface area.

| a1 | Time | GMD | SA | IKV | BD | IP | APS | WSI | L* | ΔE* |

|---|---|---|---|---|---|---|---|---|---|---|

| Time | 0.884 | 0.884 | 0.887 | −0.909 | 0.873 | −0.974 | 0.486 | −0.933 | 0.877 | |

| GMD | 0.884 | 0.999 | 0.953 | −0.901 | 0.953 | −0.918 | 0.539 | −0.739 | 0.667 | |

| SA | 0.884 | 1.000 | 0.999 | −0.900 | 0.953 | −0.917 | 0.541 | −0.740 | −0.740 | |

| KV | 0.887 | 0.999 | 0.999 | −0.894 | 0.946 | −0.916 | 0.574 | −0.748 | 0.671 | |

| BD | −0.909 | −0.901 | −0.900 | −0.894 | −0.905 | 0.931 | −0.328 | 0.765 | −0.718 | |

| IP | 0.873 | −0.901 | 0.953 | 0.946 | −0.905 | −0.917 | 0.366 | −0.730 | 0.750 | |

| APS | −0.974 | −0.918 | −0.917 | −0.916 | 0.931 | −0.917 | −0.427 | 0.881 | −0.824 | |

| WSI | 0.486 | 0.539 | 0.541 | 0.574 | −0.328 | 0.366 | −0.427 | −0.532 | 0.382 | |

| L* | −0.933 | −0.740 | −0.748 | −0.730 | −0.739 | −0.532 | 0.881 | −0.532 | 0.765 | |

| ΔE* | 0.877 | 0.668 | 0.671 | 0.750 | 0.667 | 0.382 | −0.824 | 0.382 | −0.938 |

Table 1.

| a2 | Time | GMD | SA | IKV | BD | IP | APS | WSI | L* | ΔE* |

|---|---|---|---|---|---|---|---|---|---|---|

| Time | 0.878 | 0.880 | 0.886 | −0.903 | 0.863 | −0.942 | 0.766 | −0.997 | 0.990 | |

| GMD | 0.878 | 1.000 | 0.999 | −0.992 | 0.990 | −0.933 | 0.830 | −0.883 | 0.871 | |

| SA | 0.880 | 1.000 | 1.000 | −0.992 | 0.990 | −0.934 | 0.831 | −0.886 | −0.886 | |

| KV | 0.886 | 0.999 | 1.000 | −0.992 | 0.991 | −0.936 | 0.839 | −0.892 | 0.880 | |

| BD | −0.903 | −0.992 | −0.992 | −0.992 | −0.977 | 0.946 | −0.821 | 0.911 | −0.903 | |

| IP | 0.863 | 0.990 | 0.990 | 0.991 | −0.977 | −0.922 | 0.834 | −0.863 | 0.846 | |

| APS | −0.942 | −0.933 | −0.934 | −0.936 | 0.946 | −0.922 | −0.766 | 0.939 | −0.932 | |

| WSI | 0.766 | 0.830 | 0.831 | 0.839 | −0.821 | 0.834 | −0.766 | −0.774 | 0.751 | |

| L* | −0.997 | −0.883 | −0.886 | −0.892 | 0.911 | −0.863 | 0.939 | −0.774 | −0.996 | |

| ΔE* | 0.990 | 0.871 | 0.874 | 0.880 | −0.903 | 0.846 | −0.932 | 0.751 | −0.996 |

Table 2.

The correlation coefficients between some geometric, gravimetric, and color properties of sweet maize a2 toasted by microwaves.

GMD: geometric mean diameter; SA: surface area; KV: kernel volume; BD: bulk density; IP: internal porosity; APS: average particle size; WSI: water-soluble index; L*: lightness; ΔE*; overall color difference.

Figure 5.

Microwave heating-toasting effect on geometric mean diameter GMD and its correlation with other time-related variables determined in floury and sweet maize subjected to 492 W for 390 seconds: (a) GMD versus time, (b) bulk density versus GMD, (c) internal porosity versus GMD, and (d) average particle size versus GMD. Unpublished plots.

Figure 6.

Microwave heating-toasting effect on individual kernel volume and its correlation with other time-related variables determined in floury and sweet maize subjected to 492 W for 390 seconds: (a) kernel volume versus time, (b) bulk density versus kernel volume, (c) internal porosity versus kernel volume, and (d) average particle size versus kernel volume. Unpublished plots.

Figure 7.

Microwave heating-toasting effect on bulk density and its correlation with other direct and indirect time-related variables determined in floury and sweet maize subjected to 492 W for 390 seconds: (a) bulk density versus time, (b) internal porosity versus bulk density, (c) average particle size versus bulk density, and (d) average particle size versus internal porosity. Unpublished plots.

Figure 8.

Microwave heating-toasting effect on lightness (L*) of the CIE color space and its correlations with other time-related variables determined in floury and sweet maize subjected to 492 W for 390 seconds: (a) L* versus time, (b) water-soluble index (WSI) versus L*, (c) color difference (ΔE*) versus L*, and (d) L* versus surface area. Unpublished plots.

3.3 Practical application on raw microwave maize

All raw materials that, in the form of whole kernels, are transformed into first-generation snack foods by conventional toasting or frying methods can be packaged for toasting in a microwave oven, e.g., maize, chickpeas, beans, peanuts, and some nuts.

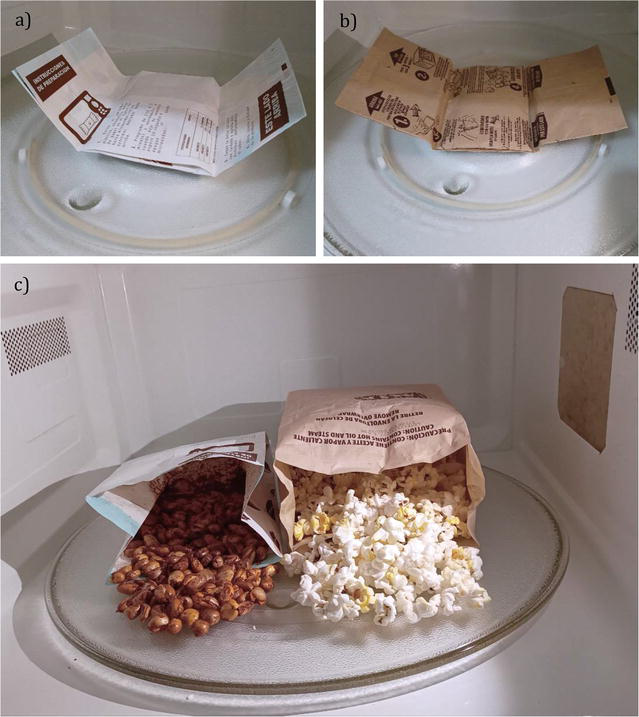

There are two practical applications to the types of maize. One is very recent with floury maize (

Figure 9.

Raw maize kernels packed for microwave oven: (a) microwaveable packaging with floury maize kernel, (b) microwaveable packaging with popcorn, and (c) first-generation snack foods made with floury maize and popcorn.

3.4 Microwave packages for raw kernels

Many patents are related to microwave popcorn bags [26, 27, 28], so packaging refers to a bag with the basic structure for packaging raw popcorn kernels. A bag of this type is designed to unfold and increase its volume due to the steam generated during the toasting of the kernel. The free end vertices of the bag have a rounded configuration to prevent blocking with the oven cavity walls due to increased volume. The bag’s volume depends on the moisture content and the expansion capacity of the kernel. Therefore, the total width and the width of the folds are the parameters that can be varied in packaging for toasting other kernels with a reduced expansion volume, e.g., the reduced kernel expansion in floury maize compared with popping expansion in popcorn (Figure 9).

4. Innovation in microwave ovens for household and industrial use

Based on traditional toasting, the heat from the hot pan is transmitted evenly to the kernels through constant manual movement with a paddle. In this way, all kernels reach an approximately similar heating temperature. Consequently, continuous position changes of the kernels within the packaging are required during microwave toasting. Microwave technology in the toasting process aims to reduce operation time and improve final product quality. However, raw kernel packaged for microwave is challenging for household oven technology powered by the 2450 MHz frequency spectrum. The household microwave oven consists of a magnetron, a waveguide, and an aperture to a rectangular cavity. The microwave radiation, generated by magnetron produces reflection that leads to a nonuniform heating pattern even in standardized sample sizes [29]. According to the literature, the non-uniform distribution of the electromagnetic field due to the cavity geometry requires effective systems to achieve a uniform heating temperature [30], and attain adequate sample movement [31].

Likewise, a 915 MHz frequency is generated by a magnetron for industrial processes with a non-uniform electromagnetic field distribution. Therefore, the current studies aim to overcome this limitation. Solid-state generators have been recently introduced as capable of performing electronic control over the frequency and magnitude of the excited microwave field and heating processes for both continuous and pulse operations [29]. The narrow and stable bandwidth of the solid-state generator produces a single standing wave pattern, resulting in stable and predictable food heating patterns, inferring that the available information provides fundamental insights into solid-state microwave heating [32]. Considering the magnetron as a fundamental element in microwave technology, it is estimated that the increase in magnetrons in specific positions makes it possible to overcome the problem of non-uniform temperature distribution in the cavity [33]. Concerning the non-uniform electromagnetic field distribution caused by reflection at the cavity walls, its geometry seems to be decisive in how microwave heating is distributed, so sample rotational movement, cavity geometry, and frequency can affect temperature and electromagnetic field distribution at the industrial scale [30].

On the other hand, the advances in uniform microwave heating aim to improve the volumetric heating of solid samples with rotary motion devices adaptable to all kinds of microwave cavities irrespective of geometric shapes [34]. Therefore, microwave toasting suggests developing theoretical or empirical models related to this process. However, the assumptions required to apply Fick’s second law of diffusion in drying processes do not satisfactorily describe the maize kernel toasting by microwave heating. In raw maize packaged for microwaves, there is influence from both the geometry of the packaging and the geometry of the individual kernels. In addition, microwave toasting with intermittent manual shaking causes an increase in maize kernel volume ascribed to internal porosity generated by water migration [2]. The toasting kinetics in raw microwave maize inside the packaging is a challenge for future understanding. The first insight is the wide range of variables related to microwave toasting time determined for microwave-packaged maize [23, 24]. The geometric shape of the product can also affect the reflection of microwave electromagnetic energy, power absorption efficiency, and penetration depth into the product from surface area [29]. The influence of sample size and geometry on the reflection of microwave electromagnetic radiation is still an unexplored field. The available information focuses on searching for optimal food geometries with high moisture content and specific sizes, such as potato tubers and portions of meat or fish. It is expected that the findings achieved will contribute to the design of packaged and unpackaged product geometries [35].

5. Microwave toasting for industrial application

Most current studies on kernel toasting apply the fundamental principles of microwave drying on a single layer of products spread on flat surfaces [36, 37, 38, 39], so the drying irradiation fundament can be used in microwave industrial-scale toasting operations. The principle of microwave drying has generated a large amount of information worldwide. However, microwave toasting for industrial scaling requires further research, consistent with the growing trend of publications on microwave toasting observed in Figure 2, reported at the beginning. Consequently, this section highlights the following issues: (1) microwave toasting to make first-generation snack foods; (2) microwave expansion phase to obtain third-generation snack foods; (3) the toasting required in the cocoa and coffee industries; (4) the toasting of whole kernels, whether these are cereals, minor kernels or legumes, for the development of new ingredients rich in biocomponents or techno-functional properties; (5) inactivation of antinutritional compounds by toasting effect; and (6) the formation of acrylamide. Table 3 summarizes the studies related to microwave technology with application perspectives in industrial kernel toasting.

| Raw material | Higher goal | Microwave experiments | Relevant results | References |

|---|---|---|---|---|

| Sunflower seeds ( | To examine the effect of different toasting methods on sensory attributes, texture, and fat properties. | Time with four levels: 5, 10, 20, and 25 minutes. Power with three levels: 500, 600, 800 W. Time with three levels: 4, 6, and 8 minutes. | Microwave toasting did not diminish the sensory quality of the product. | [7] |

| Chickpeas | To determine the effect of different roasting methods on the compositions, powder properties, texture, and sensorial properties | Temperature at 250°C. Power with three levels: 100, 300, and 600 W. Time with three levels: 3, 5, and 7 min. Microwave study treatment with additional toasting at 250°C. | The treatment to 300 W for 3 minutes and additional toasting at 250°C is reported for chickpea snack foods with the highest sensory scores. | [8] |

| Peanuts, hazelnuts, walnuts | To improve the taste of the snack foods and results in energy with microwave toasting. | Power in three levels: 500, 600, and 800 W. Time in three levels: 4, 6, and 8 min. Time with four levels: 5, 10, 20, and 25 min. | Microwaving can ensure effective protection against hydrolytic rancidity and deterioration of primary oxidation compounds. | [7] |

| A base mixture of blue corn and powdered spinach reached with black bean | To evaluate the combined process of extrusion and microwave expansion on the third-generation snack food properties | Black beans in three levels: 11, 22, and 33%. Power of 1000 W for 23 s | It is possible to produce 3G snacks with bioactive properties and improved protein quality using a combination of extrusion cooking and microwave heating. | [40] |

| Corn flakes with 20% | To study the toasting of cornflakes by | Power in three levels: 504, 672, and 840 W. | The results suggest that microwave toasting could be a good alternative | [10] |

Table 3.

Summary of the perspectives of microwave technology application in the kernel toasting industry.

5.1 Microwave toasting to make first-generation snack foods

Microwave toasting to obtain first-generation snack foods (1G) is a viable application in batch and continuous operations. The knowledge generated on the fundamentals of the food toasting process [22, 41] and the different experimental findings [7, 8, 42] have stimulated microwave oven developers to work on innovative designs with devices required in the experimentation laboratories and for the industrial scaling of microwave findings.

5.2 Microwave expansion phase to obtain third-generation snack foods

The microwave expansion phase to develop third-generation snack foods is a healthy way of improving nutrition value, texture properties, and sensory attributes [10, 43] . Thus, extruded, or pelleted products can be expanded indirectly by microwave heating-toasting phase in the snack food technology [43]. Third-generation snack foods are made with non-traditional ingredient formulations for typical extrusions. New or exotic ingredients can be incorporated to obtain products differentiated in nutritional value, texture properties, and sensory attributes [40]. However, the extrudates are intermediate products (pellets, flakes) that follow the next expansion phase by microwave heating-toasting, achieving fortification in nutritional value, new texture properties, and specific sensory attributes.

5.3 The toasting required in the cocoa and coffee industries

Toasting is an essential step in the cocoa industry that includes the combined use of time-temperature profiles to optimize the toasting degree. Toasting causes physicochemical and microstructural changes in cocoa beans that ensure their characteristic aromas and flavors. A comprehensive review of the state of the art of cocoa toasting provides important insights into the use of microwaves in cocoa toasting [11], and allows consider the microwave technology to toast cocoa beans for future studies. The impact of microwave-toasting cocoa beans on the aroma and phytochemical profile of dark chocolates (70% cocoa) is reported compared to chocolates produced from cocoa beans toasted by convection at 130°C for 30 minutes. Indeed, the results validate the use of microwave toasting for cocoa beans and project as a promising technological step that can be scaled with further research to improve the specialty sensory characteristics in chocolate production [11, 44].

Coffee is a hot drink consumed worldwide. It is made from toasted coffee beans, and its characteristic aroma and flavor depend on specialty compounds developed during the toasting step [45]. Thus, toasting is one of the critical steps for the processing of coffee beans to be used in beverages. There are limited studies on coffee bean toasting by microwaves. However, the comparative results between conventional and microwave toasting reveal a similar effect on volatile components and less caffeine and chlorogenic acid reduction with microwave toasting [46], so microwave radiation can be used as an innovative toasting technology for coffee beans.

5.4 The toasting of whole kernels for the development of new ingredients

The heating and toasting of whole kernels are topics of current research that seek to establish specific conditions to modulate changes in the multi-component matrix of each type of kernel [17]. Cereals [36], minor kernels [19], legumes [8, 47], oilseeds [48, 49], and other seeds can be potential sources of new food ingredients through microwave heating and toasting. The studies carried out in recent years show the effect of microwave technology on the microstructure, composition, bioactive components, and physicochemical properties of different kernels [47, 48, 49, 50].

5.5 Inactivation of antinutritional compounds by toasting effect

Some starchy kernels modified (treated) with dry heat can exhibit specific physiological functions such as antidiabetic and anti-inflammatory activity from residues encapsulated in starch-protein structures [17]. For some legumes (pulses), the thermal treatment contributes to deactivating antinutritional factors such as tannin, protease inhibitors (trypsin, chymotrypsin), and phytic acid, while preserving the functional properties of legumes. In summary, these works provide data support to investigate microwave use to deactivate antinutritional factors in raw materials [21, 51].

5.6 Acrylamide formation

Acrylamide is classified as a potential carcinogen (Group 2A) in humans. However, little is still known about the levels of acrylamide in different foods and their potential risk [52, 53]. The major pathway of acrylamide formation seems to be the Maillard reaction, in particular, in the presence of the amino acid asparagine [54]. Therefore, the acrylamide content in cereals depends on several factors, such as the level of free asparagine, the composition of the food matrix, and the time-temperature profiles of the thermal treatments [52]. Toasting is important in the nut industry to develop flavor and texture. However, the Maillard reaction may result in acrylamide formation. For example, raw and salted pistachios treated under hot air, infrared, and microwave toasting present the highest amounts of acrylamide in raw pistachios toasted by infrared. In contrast, a lower amount is observed for the microwave irradiation [55]. Consequently, research on opportunities for the application of microwave toasting technology should have acrylamide content as another measurement variable.

6. Conclusion and future prospective

This chapter shows that toasting kernels, seeds, and nuts is a current topic and has sparked interest worldwide, focusing on snack foods and developing ingredients with new properties. Except for popcorn and its natural popping capacity, microwave toasting of packaged whole kernels is an unexplored field. Its importance is based on the opportunity to prepare different types of first-generation snack foods at home. Based on the popularity achieved by the microwave oven for home use and the acceptance of first-generation snack food among consumers, innovation in the microwave oven for home use is a challenge for microwave technology. The lack of uniformity in volumetric microwave heating due to the reflection of electromagnetic radiation is recognized in domestic ovens and conveyor belts for industrial applications. Uniform temperature distribution in packaged and unpacked food and the heating space is the highest goal of the advances. The experiments could be designed with independent and dependent variables based on the source of microwave generation, the microwave heating space specifications, and the food’s properties, including type, shape, and size.

Acknowledgments

My gratitude goes to the Vice-Rectorate of Research, Doctorates, and Innovation of the Central University of Ecuador.

References

- 1.

Breslin JC, Knott K. 15 - toasting. In: Perdon AA, Schonauer SL, Poutanen KS, editors. Breakfast Cereals and How they Are Made. 3rd ed. Oxford: AACC International Press; 2020. pp. 299-321 - 2.

Lara N, Ruales J. Physical and hydration properties of specialty floury and sweet maize kernels subjected to pan and microwave toasting. Journal of Cereal Science. 2021; 101 :103298 - 3.

Lipan L, Cano-Lamadrid M, Vázquez-Araújo L, Łyczko J, Moriana A, Hernández F, et al. Optimization of roasting conditions in hydroSOStainable almonds using volatile and descriptive sensory profiles and consumer acceptance. Journal of Food Science. 2020; 85 :3969-3980 - 4.

Xu Y, Liao M, Wang D, Jiao S. Physicochemical quality and volatile flavor compounds of hot air-assisted radio frequency roasted almonds. Journal of Food Processing and Preservation. 2020; 44 :e14376 - 5.

Dean LL, Campbell RA, Stoner-Harris T, Hung Y-C, Hendrix KW, Adhikari K. Profiling seventeen cultivars of roasted peanuts by descriptive sensory and flavor volatile analyses. Measurement: Food. 2023; 11 :100105 - 6.

Liao M, Zhao YH, Xu Y, Gong C, Jiao S. Effects of hot air-assisted radio frequency roasting on nutritional quality and aroma composition of cashew nut kernels. LWT-Food Science and Technology. 2019; 116 :108551 - 7.

Goszkiewicz A, Kołodziejczyk E, Ratajczyk F. Comparison of microwave and convection method of roasting sunflower seeds and its effect on sensory quality, texture and physicochemical characteristics. Food Structure. 2020; 25 :100144 - 8.

Tekgül Barut Y, Çalışkan Koç G, Rayman Ergün A, Bozkır H, Pandiselvam R. Effect of different roasting methods on the proximate by composition, flow properties, amino acid compositions, colour, texture, and sensory profile of the chickpeas. International Journal of Food Science & Technology. 2023; 58 :482-492 - 9.

Bhattacharya S. Chapter 12 - processes and machinery. In: Bhattacharya S, editor. Snack Foods. London: Academic Press; 2023. pp. 321-382 - 10.

González LC, Loubes MA, Tolaba MP. Evaluation of microwave toasting of corn flakes. Journal of Food Processing and Preservation. 2018; 42 :e13671 - 11.

Peña-Correa RF, Ataç Mogol B, Fogliano V. The impact of roasting on cocoa quality parameters. Critical Reviews in Food Science and Nutrition. 2022:1-14. Published online 16 November 2022 [In press] - 12.

Castro-Alayo EM, Idrogo-Vasquez G, Siche R, Cardenas-Toro FP. Formation of aromatic compounds precursors during fermentation of criollo and Forastero cocoa. Heliyon. 2019; 5 :e01157 - 13.

Velasquez-Reyes D, Rodriguez-Campos J, Avendano-Arrazate C, Gschaedler A, Alcazar-Valle M, Lugo-Cervantes E. Forastero and criollo cocoa beans, differences on the profile of volatile and non-volatile compounds in the process from fermentation to liquor. Heliyon. 2023; 9 :e15129 - 14.

Flores-Chávez B, Garza-López PM, Angel-Cuapio A, Hernández-León S, Espinosa-Zaragoza S, Villafaña-Rivera FJ, et al. Analysis verbal sensory methods in the evaluation of organic coffee with different roasting intensities. International Journal of Food Properties. 2022; 25 :708-716 - 15.

Palma FD, Iacono F, Toffanin C, Ziccardi A, Magni L. Scalable model for industrial coffee roasting chamber. Procedia Computer Science. 2021; 180 :122-131 - 16.

Liao Y-C, Kim T, Silva JL, Hu W-Y, Chen B-Y. Effects of roasting degrees on phenolic compounds and antioxidant activity in coffee beans from different geographic origins. LWT-Food Science and Technology. 2022; 168 :113965 - 17.

Li L, Wang Q , Liu C, Hong J, Zheng X. Effect of oven roasting on major chemical components in cereals and its modulation on flour-based products quality. Journal Food Science. 2023; 88 :2740-2757 - 18.

Fukui M, Islam MZ, Lai H-M, Kitamura Y, Kokawa M. Effects of roasting on storage degradability and processing suitability of brown rice powder. LWT-Food Science and Technology. 2022; 161 :113277 - 19.

Kheto A, Joseph D, Islam MZ, Dhua S, Das R, Kumar Y, et al. Microwave roasting induced structural, morphological, antioxidant, and functional attributes of quinoa ( Chenopodium quinoa Willd). Journal of Food Processing and Preservation. 2022;46 :e16595 - 20.

Kaur R, Prasad K. Process optimization for the development of traditionally roasted chickpea flour for meal replacement beverages. Food Chemistry Advances. 2023; 3 :100452 - 21.

Sharma S, Kataria A, Singh B. Effect of thermal processing on the bioactive compounds, antioxidative, antinutritional and functional characteristics of quinoa ( Chenopodium quinoa ). LWT-Food Science and Technology. 2022;160 :113256 - 22.

Das PP, Duarah P, Purkait MK. 5 - fundamentals of food roasting process. In: Jafari SM, editor. High-Temperature Processing of Food Products. Cambridge: Woodhead Publishing; 2023. pp. 103-130 - 23.

Lara N, Osorio F, Ruales J. Variables related to microwave heating-toasting time and water migration assessment with kernel size approaches of specialty maize types. Journal of the Science of Food and Agriculture. 2022; 102 :6088-6099 - 24.

Lara N, Portilla A, Osorio F, Ruales J. Modeling of the microwave heating-toasting time-related variables and characterization of non-isothermal rheological properties of floury and sweet specialty maize kernels. Applied Food Research. 2022; 2 :100119 - 25.

Lara N, Vizuete K, Debut A, Chango I, Campaña O, Villacrés E, et al. Underutilized maize kernels ( Zea mays L. var.Amylacea and var.saccharata ) subjected to pan and microwave toasting: A comparative structure study in the whole kernel. Journal of Cereal Science. 2021;100 :103249 - 26.

Almog Y. Method and Package for Evenly Roasting Seeds in a Microwave, France. European Patent No. EP 3 861 832 B1. Paris, France: Europen Patent Office; 2021 - 27.

France DW. Microwave Popcorn Bag, Canada. Google Pantents No.CA3091430A1. 2019 - 28.

Galceran Martorell C. Bag for Cooking Corn Grains in a Microwave, United States. U.S. Patent No. US20190009971A1. Washington, DC: U.S. Patent and Trademark Office; 2019 - 29.

Koutchma T. Chapter 2 - heating characteristics of microwave systems and dielectric properties of foods. In: Koutchma T, editor. Microwave and Radio Frequency Heating in Food and Beverages. London: Academic Press; 2023. pp. 29-53 - 30.

Altin O, Skipnes D, Skåra T, Erdogdu F. A computational study for the effects of sample movement and cavity geometry in industrial scale continuous microwave systems during heating and thawing processes. Innovative Food Science & Emerging Technologies. 2022; 77 :102953 - 31.

Ye J, Lan J, Xia Y, Yang Y, Zhu H, Huang K. An approach for simulating the microwave heating process with a slow- rotating sample and a fast-rotating mode stirrer. International Journal of Heat and Mass Transfer. 2019; 140 :440-452 - 32.

Zhou X, Tang Z, Pedrow PD, Sablani SS, Tang J. Microwave heating based on solid-state generators: New insights into heating pattern, uniformity, and energy absorption in foods. Journal of Food Engineering. 2023; 357 :111650 - 33.

Salvador AA, Teleken JT, Travassos XL, Avila SL, Carciofi BAM. Multiphysics modeling to assist microwave cavity design for food processing. Journal of Electrical and Computer Engineering. 2022; 2 :1-10 - 34.

Ye J, Xia Y, Yi Q , Zhu H, Yang Y, Huang K, et al. Multiphysics modeling of microwave heating of solid samples in rotary lifting motion in a rectangular multi-mode cavity. Innovative Food Science & Emerging Technologies. 2021; 73 :102767 - 35.

Deng A, Li X, Qiu W, Li L, Tao N, Jin Y. Geometry optimization of microwavable food to improve heating uniformity. Journal of Food Engineering. 2024; 369 :111945 - 36.

An N-N, Li D, Wang L-J, Wang Y. Microwave irradiation of corn kernels: Effects on structural, thermal, functional and rheological properties of corn flour. Food Hydrocolloids. 2023; 143 :108939 - 37.

Arballo JR, Campañone LA. 7 - application of microwave processing in the food industry. In: Jafari SM, editor. Emerging Thermal Processes in the Food Industry. Cambridge: Woodhead Publishing; 2023. pp. 165-226 - 38.

Gaikwad PS, Sunil CK, Negi A, Pare A. Effect of microwave assisted hot-air drying temperatures on drying kinetics of dried black gram papad (Indian snack food). Applied Food Research. 2022; 2 :100144 - 39.

Shao Z, Song Y, Hong Y, Tao S, Sun J, Liu C, et al. The extension of vacuum microwave drying time improved the physicochemical properties, in vitro digestibility and antioxidant activity of brown rice flour. LWT-Food Science and Technology. 2023; 184 :115023 - 40.

Neder-Suárez D, Vázquez-Rodríguez JA, González-Martínez BE, Meléndez-Pizarro CO, Hernández-Ochoa LR, Murowaniecki-Otero D, et al. Effect of using alternative flours on the development and characteristics of a third-generation snacks. Food Chemistry Advances. 2024; 4 :100571 - 41.

Kutlu N, Pandiselvam R, Saka I, Kamiloglu A, Sahni P, Kothakota A. Impact of different microwave treatments on food texture. Journal of Texture Studies. 2022; 53 :709-736 - 42.

Goszkiewicz A, Kochanska E, Korczak K, Potapov VО, Prasol S. Influence of microwave treatment on quality parameters of snacks food. Impact issuees. Acta Innovations. 2020; 36 :64-80 - 43.

Panak Balentic J, Babic J, Jozinovic A, Ackar D, Milicevic B, Muhamedbegovic B, et al. Production of third-generation snacks. Croatian Journal of Food Science and Technology. 2018; 10 :98-105 - 44.

Lemarcq V, Monterde V, Tuenter E, Walle DVD, Pieters L, Sioriki E, et al. Flavor diversification of dark chocolate produced through microwave roasting of cocoa beans. LWT-Food Science and Technology. 2022; 159 :113198 - 45.

Ganju E, Chawla K, Yang S, Chawla N. Time-resolved roasting-induced microstructural evolution of arabica coffee beans from Brazil, Colombia, and Ethiopia captured using x-ray computed micro-tomography. Journal of Food Engineering. 2024; 361 :111733 - 46.

Yoon S, Jeong H, Jo SM, Hong SJ, Kim YJ, Kim JK, et al. Chemosensoric approach for microwave- or oven-roasted Coffea arabica L. (cv.Yellow Bourbon ) using electronic sensors. LWT-Food Science and Technology. 2022;167 :113844 - 47.

Najib T, Heydari MM, Tu K, Meda V. Modification in starch structure of soaked and germinated lentil seeds under various thermal processing methods, including conventional, microwave, and microwave-assisted techniques. Food Chemistry Advances. 2023; 2 :100267 - 48.

Yin WT, Yang CJ, He XY, Zhao YH, Liu HM, Zhai ZQ , et al. Comparison of microwave and hot-air roasting on microstructure of sesame seed, aroma-active, hazardous components, and sensory perception of sesame oil. Food Chemistry X. 2023; 20 :101045 - 49.

Yin W-T, Shi R, Li K, Wang X-D, Wang A-N, Zhao Y-H, et al. Effect of microwave pretreatment of sunflower kernels on the aroma-active composition, sensory quality, lipid oxidation, tocopherols, heterocyclic amines and polycyclic aromatic hydrocarbons of sunflower oil. LWT-Food Science and Technology. 2022; 170 :114077 - 50.

Özcan MM, Uslu N. The effect of oven and microwave roasting on bioactive properties, phenolic components and fatty acid compositions of soybean and peanut seeds. Food and Humanity. 2024; 2 :100250 - 51.

Manikpuri S, Kheto A, Sehrawat R, Gul K, Routray W, Kumar L. Microwave irradiation of guar seed flour: Effect on anti-nutritional factors, phytochemicals, in vitro protein digestibility, thermo-pasting, structural, and functional attributes. Journal of Food Science. 2024; n/a - 52.

Mesias M, Delgado-Andrade C, Morales FJ. An updated view of acrylamide in cereal products. Current Opinion in Food Science. 2022; 46 :100847 - 53.

Žilić S. Chapter 10 - acrylamide in soybean products, roasted nuts, and dried fruits. In: Gökmen V, Mogol BA, editors. Acrylamide in Food. 2nd ed. London: Academic Press; 2024. pp. 201-222 - 54.

Koutchma T. Chapter 4 - Microwave heating and quality of food. In: Koutchma T, editor. Microwave and Radio Frequency Heating in Food and Beverages. London: Academic Press; 2023. pp. 81-111 - 55.

Asadi S, Aalami M, Shoeibi S, Kashaninejad M, Ghorbani M, Delavar M. Effects of different roasting methods on formation of acrylamide in pistachio. Food Science & Nutrition. 2020; 8 :2875-2881